The global automated stationary NDT & inspection systems market is expected to grow from USD 767.4 million in 2025 to USD 1,195.9 million by 2030, registering a robust CAGR of 9.3%.This expansion is being propelled by rising demand for real-time, inline quality assurance in high-throughput environments, coupled with stringent safety and regulatory standards across heavy industries

Key Growth Drivers: Inline Inspection and Industry Mandates

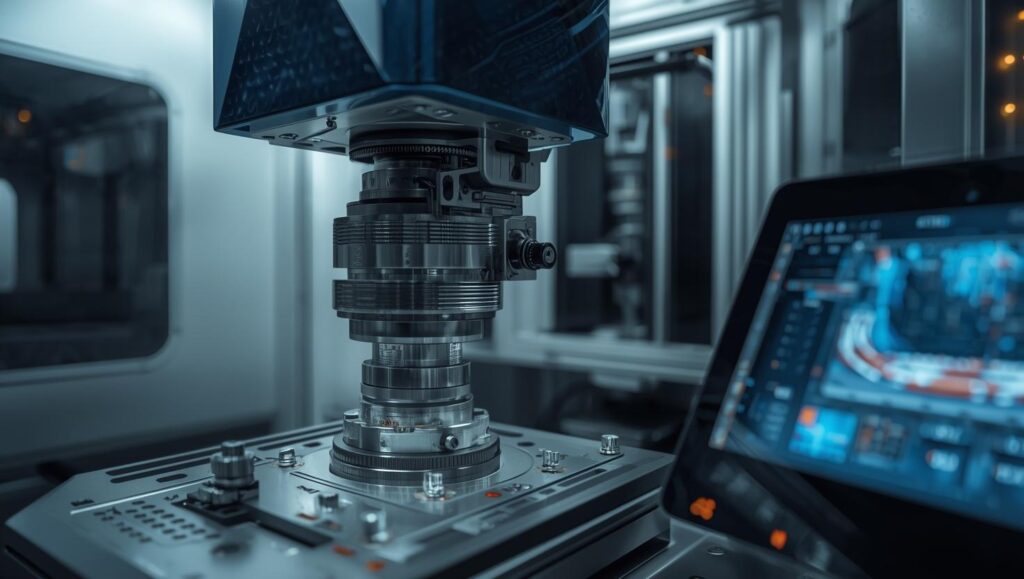

Automated systems enabled with ultrasonic testing (UT), eddy current testing (ECT), and machine vision are increasingly relied upon for non-invasive, accurate defect detection. These inline setups boost production efficiency, reduce waste, and improve traceability — becoming essential to zero-defect manufacturing especially under heightened regulatory scrutiny

Technology Trends: UT Reigns, ECT Accelerates

Ultrasonic Testing (UT) holds the largest market share in 2025, recognized for its precision, versatility, and widespread industrial adoption—particularly through PAUT and automated scanner integration

Meanwhile, Eddy Current Testing (ECT) is emerging as the fastest-growing technology segment. Its ability to perform rapid, non-contact inspections on conductive materials makes it ideal for metals, rail, and aerospace applications

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=233564506

Modular Systems: The Future of Inspection Flexibility

A compelling market opportunity lies in deploying modular, multi-technology inspection platforms. Capable of integrating technologies such as UT, PAUT, ECT, and machine vision, these modular systems support diverse inspection needs via scalable architecture. Built for adaptability and future expansion, they offer industries increased flexibility while safeguarding long-term ROI

Asia Pacific: The Emerging Powerhouse

The Asia Pacific region is projected to hold the largest market share by 2025. Rapid industrialization, infrastructure investments like “Make in India” and “China Manufacturing 2025”, and strong adoption of automation are primary drivers. In contrast, North America and Europe see steady adoption due to aging infrastructure and regulatory enforcement

Industry Hurdles: Complexity & Skill Gaps

Despite the promising outlook, the industry faces obstacles. Technical integration complexity and customization challenges pose significant barriers—tailoring systems to varied production lines, aligning with unique workflows, and syncing multiple NDT modalities increase both time and cost

Additionally, the scarcity of field-proven use cases and a shortage of skilled system integrators challenge broader market adoption and confidence

Ecosystem Players Driving Innovation

The Major companies operating in the global automated stationary NDT & inspection systems companies include EVIDENT (Japan), Waygate Technologies (US), FOERSTER (Germany), Eddyfi (Canada), and Magnetic Analysis Corporation (US). These companies power innovation through product development, integration capabilities, and strategic industry collaborations

Looking Ahead: A Smarter, Safer, and More Efficient Inspection Future

The Automated Stationary NDT & Inspection Systems industry is poised for strong momentum through 2030. With real-time inline inspection, modular multi-tech platforms, and fast-growing regions like Asia Pacific at the helm, the industry is entering a phase of accelerating sophistication.

To remain competitive, stakeholders should build systems that are flexible, scalable, and integrated with AI and predictive analytics. Overcoming integration challenges and fostering skilled specialist ecosystems will be key to driving broader adoption and unlocking the full potential of automated inspection in the coming years.

FAQs – Automated Stationary NDT & Inspection Systems Market

1. What are Automated Stationary NDT & Inspection Systems?

These are non-destructive testing (NDT) systems permanently installed at specific points in industrial processes to inspect and assess components or materials without moving them. They are used for inline, continuous, or batch inspections in manufacturing, ensuring defect-free production without compromising structural integrity.

2. What is the projected market size of this industry by 2030?

The market is expected to grow from USD 767.4 million in 2025 to USD 1,195.9 million by 2030, at a compound annual growth rate (CAGR) of 9.3%.

3. Which inspection technologies are most widely used in these systems?

- Ultrasonic Testing (UT): Most widely used due to precision and versatility

- Eddy Current Testing (ECT): Fastest-growing due to its high speed and contactless testing

- Others include visual inspection, radiographic testing, and advanced sensor fusion techniques.

4. What are the key factors driving market growth?

- Demand for real-time, high-speed inspection in industries like aerospace, automotive, and energy

- Increasing emphasis on safety, quality assurance, and compliance

- Shift toward automated and smart manufacturing (Industry 4.0)

- Rising need for predictive maintenance and zero-defect production