In an era where precision, safety, and efficiency define success, manufacturers are turning to cutting-edge technologies to gain a competitive edge. One such advancement leading the transformation is the rapid adoption of automated stationary non-destructive testing (NDT) systems. No longer reserved for high-risk industries alone, these systems are becoming essential tools across manufacturing sectors—ensuring product quality, reducing risk, and driving operational excellence.

What is Automated Stationary NDT?

Non-destructive testing (NDT) refers to a range of techniques used to evaluate the properties or integrity of a material, component, or structure without causing any damage. Traditionally, these inspections have been labor-intensive and time-consuming, relying heavily on skilled human operators.

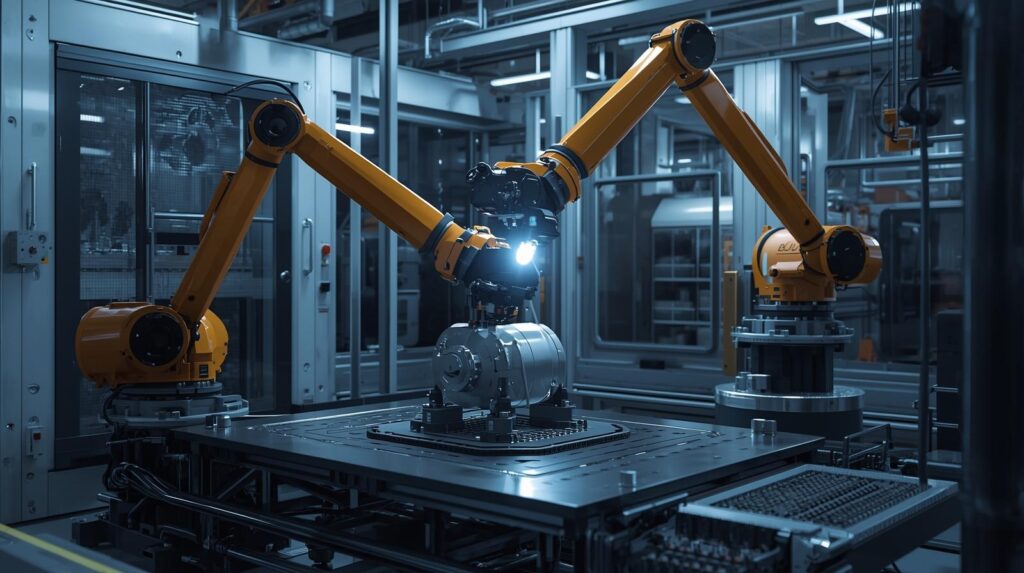

Automated stationary NDT systems, however, offer a modern alternative. Installed at fixed inspection stations within a manufacturing line, these systems leverage a combination of robotics, sensors, high-resolution imaging, ultrasound, X-ray, and increasingly, AI-driven analytics, to perform inspections quickly, consistently, and with extreme accuracy.

The global automated stationary NDT & inspection systems market is expected to grow from USD 767.4 million in 2025 to USD 1,195.9 million by 2030, registering a robust CAGR of 9.3%.

These systems allow for inline or near-line quality control, seamlessly integrating into production workflows without slowing them down.

Why Manufacturing is Embracing Automated NDT

Manufacturing environments are under pressure to increase productivity while maintaining tight tolerances and ensuring zero-defect delivery. Automated NDT plays a crucial role in this landscape for several key reasons:

1. Speed and Efficiency

Automated NDT systems can inspect components in seconds with a consistency that human inspectors cannot match. This rapid throughput enables continuous production without bottlenecks, improving overall equipment effectiveness (OEE).

2. Accuracy and Repeatability

Manual inspection is subject to human error and fatigue. Automated systems deliver high-resolution imaging and standardized testing protocols that ensure repeatability—detecting even the smallest flaws or anomalies.

3. Data-Driven Decision Making

Modern stationary NDT systems collect vast amounts of data in real time. Through AI and machine learning algorithms, this data can be used not just for immediate quality assurance but also for predictive maintenance, trend analysis, and process optimization.

4. Cost Savings Over Time

While the initial investment in automated inspection equipment can be significant, the long-term ROI is compelling. Reduced rework, fewer recalls, minimized downtime, and lower labor costs all contribute to substantial savings.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=233564506

Applications Across Manufacturing Sectors

- Automated stationary NDT systems are being widely adopted across industries where precision and safety are paramount:

- Automotive: For inspecting weld seams, castings, and machined parts during high-speed production lines.

- Aerospace: To ensure structural integrity of critical components such as turbine blades, fuselage elements, and composite structures.

- Metal & Forging: For flaw detection in billets, tubes, and heavy cast parts using ultrasonic or eddy current testing.

- Electronics & Semiconductors: In microscopic defect analysis of PCBs and microchips using automated X-ray inspection (AXI).

- Additive Manufacturing (3D Printing): Real-time inspection during layer-by-layer printing to catch deviations early.

The Role of AI and Machine Vision in NDT

What sets next-generation automated NDT apart is the integration of AI and machine vision technologies. Smart algorithms can identify defect patterns, reduce false positives, and continuously improve detection accuracy through learning models.

For example, a system equipped with machine vision can analyze welds for cracks or porosity far more reliably than traditional inspection, while an AI model can predict tool wear based on defect trends—leading to smarter production planning and reduced waste.

This convergence of AI and NDT marks a pivotal moment for manufacturers seeking to become more proactive and intelligent in their quality control strategies.

Challenges and Considerations

Despite the clear advantages, manufacturers must navigate several challenges when implementing automated stationary NDT systems:

- Integration Complexity: Retrofitting these systems into existing lines may require significant planning and customization.

- Upfront Costs: The capital expenditure for high-end systems can be substantial, though increasingly offset by ROI.

- Skilled Workforce: While automation reduces manual inspection, it demands a new skill set for technicians trained in system management, calibration, and data analysis.

- That said, vendors are offering more modular, scalable solutions that make implementation easier—even for mid-sized manufacturers.

A Strategic Investment in Quality and Competitiveness

As global competition intensifies and quality expectations continue to rise, automated stationary NDT systems are becoming a strategic investment, not just a technical upgrade. They represent a move toward zero-defect manufacturing, enhanced compliance, and smarter production environments.

For manufacturers looking to future-proof their operations, improve traceability, and reduce costs while maintaining exceptional quality, automated NDT is more than an inspection tool — it’s a business enabler.

The rise of next-gen automated stationary NDT in manufacturing reflects the industry’s shift toward intelligent automation, precision engineering, and data-centric operations. As these systems continue to evolve with AI, machine learning, and IoT connectivity, they will play a central role in the factories of tomorrow—ensuring that every product that leaves the line meets the highest standards of safety and quality.

FAQ: Automated Stationary NDT & Inspection Systems Industry

1. What is Automated Stationary NDT?

Automated Stationary NDT (Non-Destructive Testing) refers to inspection systems that are permanently installed at fixed stations within a production or assembly line. These systems use advanced technologies—such as ultrasonic testing, X-ray, eddy current, and machine vision—to detect internal or surface-level defects in materials or components without causing damage. Automation ensures consistency, speed, and repeatability across high-volume manufacturing environments.

2. How is Automated NDT different from traditional NDT?

Traditional NDT often involves manual inspection by trained technicians, which can be time-consuming and subject to human error. In contrast, automated stationary NDT systems operate continuously, integrate directly with production lines, and provide real-time, high-precision inspection with minimal human intervention. They are ideal for high-throughput and safety-critical industries.

3. Which industries are adopting automated NDT systems?

- These systems are increasingly used in:

- Automotive (weld inspection, casting defects, assembly QA)

- Aerospace (composite material testing, turbine blade integrity)

- Metals & Forging (pipe, billet, and structural integrity testing)

- Electronics (PCB and semiconductor inspection via X-ray)

- Additive Manufacturing (layer-by-layer defect detection)

- Energy & Oil/Gas (pipeline and pressure vessel inspection)

4. What are the main benefits of using automated stationary NDT systems?

- High-speed, real-time inspection without interrupting production

- Increased accuracy and repeatability compared to manual testing

- Early detection of defects, reducing rework and scrap rates

- Lower operational costs over time through process automation

- Data analytics and traceability, enabling predictive maintenance and quality assurance

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America’s Best Management Consulting Firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. With the widest lens on emerging technologies, we are proficient in co-creating supernormal growth for clients across the globe.

Today, 80% of Fortune 2000 companies rely on MarketsandMarkets, and 90 of the top 100 companies in each sector trust us to accelerate their revenue growth. With a global clientele of over 13,000 organizations, we help businesses thrive in a disruptive ecosystem.

The B2B economy is witnessing the emergence of $25 trillion in new revenue streams that are replacing existing ones within this decade. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ‘GIVE Growth’ principle, we collaborate with several Forbes Global 2000 B2B companies to keep them future-ready. Our insights and strategies are powered by industry experts, cutting-edge AI, and our Market Intelligence Cloud, KnowledgeStore™, which integrates research and provides ecosystem-wide visibility into revenue shifts.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter , LinkedIn and Facebook .

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103, Delray Beach, FL 33445

USA: +1-888-600-6441