The Low Earth Orbit Satellite Industry is experiencing rapid growth driven by increasing demand for connectivity data services Earth observation scientific research and strategic applications. Within this expanding landscape the satellite bus plays a critical role as the backbone that supports payloads enabling sustained operations in orbit. Two core subsystems within the satellite bus are command and data handling and the electric power system. Command and data handling is responsible for processing navigation and payload commands managing onboard data flow and ensuring reliable communications between ground and space assets. The electric power system sustains the platform by generating storing and distributing energy to payloads to propulsion and to thermal control units. As operators deploy constellations and single satellites alike in LEO the performance resilience modularity and cost structure of these subsystems directly influence program timelines total cost of ownership and mission success.

Market Overview

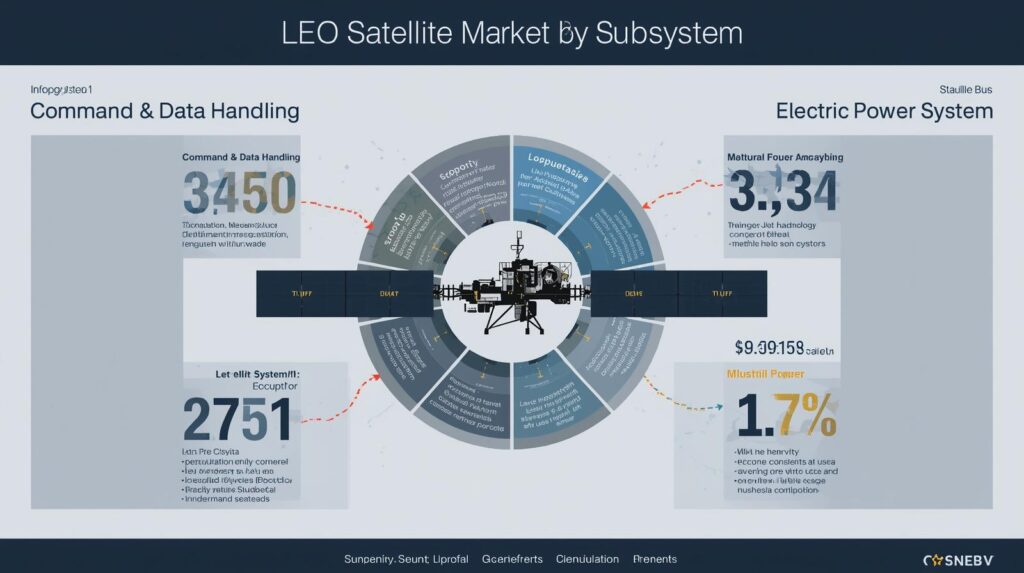

The global LEO Satellite Market was valued at USD 10.22 billion in 2024 and is projected to grow from USD 11.81 billion in 2025 to USD 20.69 billion by 2030, at a CAGR of 11.9% during the forecast period. The Low Earth Orbit satellite market is expanding rapidly as demand for fast connectivity real time data and advanced Earth monitoring grows. Positioned closer to Earth these satellites enable low latency communication high quality imaging and cost efficient deployment.

Market context and drivers

The LEO satellite market is expanding due to growing demand for broadband connectivity remote sensing Internet of things telemetry and scientific missions. Lower launch costs and advances in small satellite manufacturing have enabled rapid constellation deployment. This trend increases demand for reliable compact and cost effective bus subsystems. Command and data handling units must support higher data rates greater autonomy and enhanced cybersecurity while minimizing power draw. Electric power systems must deliver higher energy density for longer operations in sunlight and eclipse cycles and support fast recharge cycles for satellites with short revisit windows. Sustainability concerns and end of life disposal rules also shape subsystem design priorities. Overall growth is supported by commercial demand public sector investment and new business models that leverage LEO services as utility grade infrastructure.

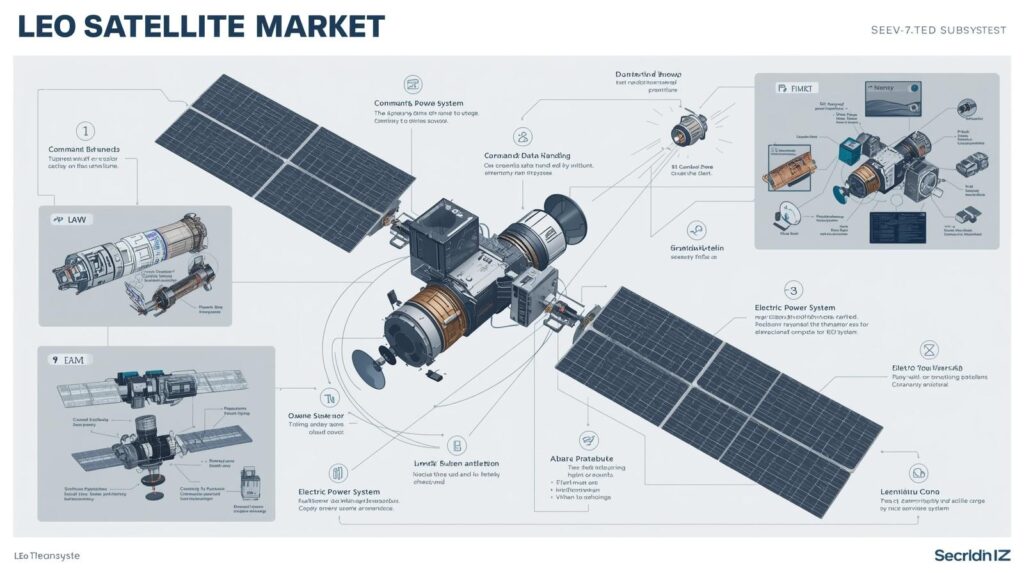

Subsystem roles and baseline requirements

Command and data handling and electric power system are foundational to satellite operations. Command and data handling provides command execution telemetry collection onboard processing data routing and timekeeping. Key requirements include low latency deterministic response for critical commands robust error detection and correction scalable interfaces to payloads and ground segment readiness for software updates. Electric power system covers generation via solar arrays energy storage typically through rechargeable batteries power distribution and power conditioning for instruments and actuators. Requirements emphasize energy density efficiency radiation tolerance thermal resilience and predictable degradation profiles. Both subsystems must meet reliability metrics defined by mission duration radiation environment expected thermal cycles and redundancy needs.

Command and data handling technology trends

The command and data handling segment is moving from single function flight computers to modular software defined avionics supporting higher levels of onboard autonomy. Processors and field programmable gate arrays are seeing steady performance growth while reducing size weight and power. Onboard data processing techniques such as data compression machine learning based feature extraction and edge analytics are being adopted to reduce downlink traffic and to enable real time decision making. Standardized interfaces and protocols are becoming common to simplify integration across payloads and to enable plug and play architecture for constellation scale manufacturing. Cybersecurity measures are being integrated at the hardware and software layers to protect command channels and sensitive payload data. Radiation hardened components remain critical for some missions while many LEO satellites adopt commercial grade parts with mitigation strategies to manage risk and reduce cost.

Electric power system technology trends

Electric power system innovation focuses on high efficiency solar cells advanced battery chemistries power electronics and smart power management. Multi junction solar cells and deployable array architectures enable higher power generation within limited surface area. Lithium based battery chemistries with improved energy density are replacing older options while newer chemistries aim to increase cycle life and safety. Power conditioning units incorporate maximum power point tracking to optimize harvest from solar arrays and advanced converters to minimize losses. Thermal management integration with power electronics improves efficiency and reliability. Modular power distribution architectures and intelligent load shedding enable graceful degradation under fault conditions. For larger LEO platforms electric propulsion compatible power systems create synergies between propulsion and power budgets.

Market segmentation and sizing considerations

The subsystem market can be segmented by satellite class smallsat microsat medium class and large platforms and by application connectivity Earth observation scientific and government. Market size estimates vary by source but growth drivers include constellation deployments for global broadband mega constellations and increasing government procurement for persistent observation. Subsystem revenue is driven by unit shipments per satellite complexity of the subsystem and aftermarket services such as upgrades spares and on ground testing. The command and data handling market benefits from higher per unit content for satellites with heavy onboard processing while electric power system revenue scales with power class and lifecycle services. Supply chain constraints and component lead times can influence market capacity creating short term price volatility.

Supplier landscape and value chain

The supplier ecosystem ranges from specialized avionics houses to vertically integrated prime contractors. Component suppliers provide processors memory power cells solar panels and converters while subsystem integrators deliver flight proven stacks ready for integration into bus designs. New entrants focusing on software defined avionics and power management tools are challenging incumbents by offering faster customization and cloud native support for ground operations. System level integrators add value through testing validation and certification services. Electronics manufacturers upstream provide semiconductors and passive components that are critical to both subsystems creating concentrated risk where a single part shortage can ripple through many programs.

Design for mass production and cost reduction

A major market pressure is the need to reduce per unit cost for constellation programs. Design for manufacturability approaches are becoming standard for command and data handling and electric power systems. Standardized modules common interfaces and automated test benches lower integration time and cost. Use of commercial off the shelf components with mission specific validation reduces procurement lead time. Battery production scale and solar panel assembly automation contribute to cost decline. However the trade off between cost and reliability must be carefully managed through accelerated life testing and mission tailored redundancy strategies.

Regulatory and standards environment

Space agencies and international bodies influence subsystem design through safety and spectrum regulations as well as end of life and debris mitigation rules. Power systems must account for safe end of life battery handling and disposal. Command and data handling systems must support encryption and authentication standards requested by national regulators for government payloads. Standardization initiatives for bus interfaces data formats and ground to space protocols reduce integration risk and enable secondary markets for repair and upgrade. Compliance with export controls and local procurement laws also impacts supplier selection and contract structures.

Manufacturing testing and qualification

Qualification testing for both subsystems encompasses thermal vacuum cycling vibration shock radiation and electromagnetic compatibility checks. Command and data handling units require extensive software verification validation and fault injection testing to prove resilience under anomalous scenarios. Electric power systems undergo charge discharge cycling depth of discharge characterization thermal stress tests and over charge protection validation. Manufacturing is increasingly supported by digital twins and model based systems engineering that allow quicker iteration and root cause analysis. Accelerated life testing helps predict degradation which is critical for warranty and end of life planning.

Supply chain risk and mitigation

Critical components such as processors memory power semiconductors and advanced battery materials can face supply constraints. Geopolitical events and export restrictions for certain electronic components elevate procurement risk. Mitigation strategies include dual sourcing long term supplier agreements stocking critical spares and early engagement with foundries for custom parts. For power systems raw material sourcing for battery electrodes and for solar cells must be secured to avoid production bottlenecks. Building supply chain transparency fosters resilience for large constellation builders.

Cybersecurity and resilience

Command and data handling systems are a primary attack surface for malicious actors. As commercial LEO services become critical infrastructure cybersecurity requirements are rising. Approaches include hardware based root of trust secure boot encrypted command channels anomaly detection and intrusion prevention frameworks. Resilience strategies include graceful degradation fallback to safe modes and distributed command architectures to prevent single point failures. Regular security patching and over the air update capabilities are essential but must be balanced against the risk of introducing new faults.

Integration with ground segment and operations

Subsystem choices influence ground segment design and operations workflows. Onboard data processing reduces downlink bandwidth requirements and simplifies ground data handling but requires integration of data formats and telemetry standards. Power management telemetry enables predictive health management and informs ground operators about battery state of health and expected lifetime. Real time command and control performance is tied to onboard processing latency and fault handling. Operators investing in ground automation can lower operational costs for large constellations but must ensure seamless interaction with onboard command and data handling systems.

Sustainability environmental and end of life considerations

Sustainable practices are increasingly demanded by regulators and customers. Battery chemistry selection affects recyclability and disposal risk at end of mission. Power systems designed for passivation and safe discharge at end of life reduce risk of on orbit explosions. Command and data handling software designed for efficient processing reduces power draw and therefore reduces required battery capacity and mass. Design for deorbit or for transfer to graveyard orbit must be part of bus level planning to meet debris mitigation guidelines.

Commercial models and aftermarket services

Aside from initial sale of subsystems recurring revenue streams include software licenses firmware updates maintenance spares and on ground test services. For command and data handling vendors offering analytics suites and remote update services create sticky relationships with operators. Power system suppliers provide battery replacement services for hosted payloads and offer state of health analytics to enable predictive maintenance. Financing models for large constellations sometimes bundle subsystems with launch and operations creating integrated procurement packages.

Regional markets and adoption patterns

North America and Europe lead in advanced subsystem technology and in government funded missions while Asia Pacific is rapidly scaling manufacturing capacity and constellation deployments for commercial services. Emerging markets in Latin America Africa and Southeast Asia are increasing demand for connectivity services driving procurement of LEO platforms. Regional supply chains shape local content requirements and influence where subsystems are manufactured and integrated. Collaboration between regional players and global suppliers is common to meet both technical and regulatory needs.

Investment and Mergers and acquisitions trends

Investors are attracted to firms that provide modular scalable avionics and power solutions that can be rapidly configured for different missions. Startups offering software defined command and data handling platforms or novel battery chemistries attract acquisition interest from larger primes looking to accelerate capability. Strategic partnerships between propulsion battery and avionics companies create integrated offers that reduce integration risk for satellite builders. Due diligence focuses on technology readiness level manufacturing capacity and customer pipeline.

Challenges and risk factors

Key challenges include long lead times for critical components component obsolescence cybersecurity threats and the trade off between low cost and high reliability. Radiation effects in LEO though less severe than deep space still require mitigation particularly for memory and processors. Battery safety remains a top concern as thermal runaway in orbit can destroy a satellite and create debris. Ensuring firmware integrity and reliable over the air updates without introducing new faults is also a major operational risk.

Future outlook and innovation opportunities

The path forward includes further adoption of autonomous onboard decision making increased use of machine learning for fault prediction and payload optimization and advances in energy storage such as solid state batteries that promise higher safety and energy density. Modular bus architectures and standardized avionics stacks will enable faster mission assembly and lower integration costs. Convergent innovation where electric power systems are cooptimized with propulsion and thermal subsystems will deliver more capable platforms with longer mission lifetimes. The market will reward suppliers that can combine performance reliability and mass production capability.

Actionable recommendations for stakeholders

For satellite operators prioritize vendors with flight heritage robust test practices and transparent supply chain management. For subsystem suppliers invest in modular designs standardized interfaces and software tooling that enable rapid customization. For investors prioritize companies demonstrating manufacturability and recurring revenue pathways such as software and analytics. For policy makers support standards that enable safe operations promote sustainable end of life handling and encourage investment in domestic manufacturing for critical components.

As LEO becomes a central layer of global communications sensing and scientific infrastructure the command and data handling and electric power system subsystems will remain key determinants of mission capability and cost. Market growth offers substantial opportunities but also demands disciplined engineering strong supply chain strategies and continuous innovation. Stakeholders that align product development with mass production readiness cybersecurity resilience and sustainability will be best positioned to capture value in the evolving LEO satellite market.