The automotive industry is in the midst of a dramatic transformation, not just in what vehicles are being built, but how they are being built. As electric vehicles, autonomous systems, and digital manufacturing converge, artificial intelligence (AI) and robotics are fundamentally reshaping the automotive manufacturing equipment market. This shift is redefining production efficiency, quality control, customization capabilities, and global competitiveness.

A New Era of Smart Manufacturing

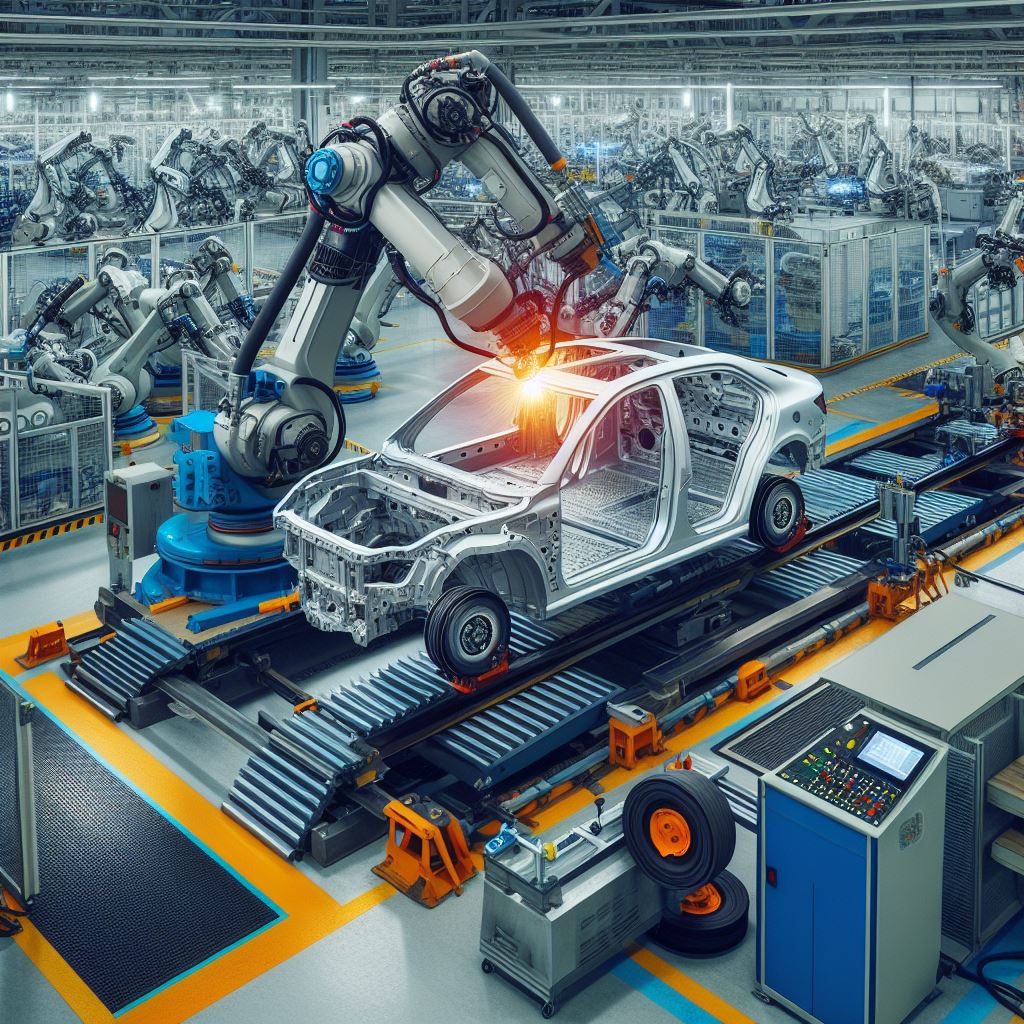

The automotive manufacturing equipment market has long been driven by precision and scale. Traditionally, automation systems have been used to perform repetitive tasks—welding, stamping, painting, and assembly—with high speed and reliability. But today’s smart factories are going a step further by integrating AI-powered robotics, transforming production lines into dynamic, learning ecosystems.

Unlike legacy automation systems, AI-enabled machines can adapt in real time. They analyze data from sensors, learn from process variations, and make decisions to optimize throughput, reduce downtime, and maintain quality. In this environment, manufacturing equipment isn’t just a tool—it’s a thinking system that improves continuously.

Robotics Take Center Stage in Production

Robotic systems are evolving from isolated workstations to collaborative production partners. In modern automotive plants, collaborative robots (cobots) work alongside human workers, sharing space and tasks without the need for complex safety barriers. These robots are equipped with vision systems and machine learning algorithms that enable them to identify parts, detect defects, and perform complex assembly tasks with unmatched precision.

Advanced robotics is also enabling the mass production of electric vehicles (EVs), which require different assembly techniques than internal combustion engine (ICE) vehicles. For example, robotic arms with thermal sensors can precisely install high-voltage battery modules, while AI ensures uniform application of adhesives critical for structural integrity.

The global automotive manufacturing equipment market is expected to be valued at USD 31.99 billion in 2025 and reach USD 41.70 billion by 2030, growing at a CAGR of 5.4% from 2025 to 2030.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=75023639

AI-Powered Quality Control and Predictive Maintenance

One of the most powerful applications of AI in the automotive manufacturing equipment market is in quality assurance. Traditional inspection methods often involve random sampling and manual checking, but AI enables real-time, 100% quality inspection. Computer vision systems equipped with deep learning can identify microscopic defects, ensuring that only flawless components move forward in the assembly line.

AI also plays a critical role in predictive maintenance. Manufacturing equipment embedded with IoT sensors continuously feeds performance data into machine learning models. These systems can detect early signs of wear or malfunction—such as unusual vibration or heat signatures—long before failure occurs. As a result, manufacturers reduce unplanned downtime and increase overall equipment effectiveness (OEE).

Flexible, Scalable, and Customizable Production

In an age of personalization, flexibility in automotive manufacturing is no longer optional. Customers demand customized features, from software settings to interior finishes. To meet this demand, factories need equipment that can switch between models and configurations seamlessly. AI-driven control systems allow for real-time adjustments, enabling a shift from mass production to mass customization.

In addition, AI and robotics make it easier to scale operations. As demand changes, manufacturers can quickly reprogram robotic cells, add or remove modules, and adjust production schedules—all without the massive capital outlays required in traditional setups.

Competitive Edge in a Global Market

As manufacturers across the globe race to become leaders in EV and autonomous vehicle production, smart factories that leverage AI and robotics are gaining a significant competitive advantage. Nations with strong automation infrastructure—such as Germany, Japan, South Korea, and China—are investing heavily in next-gen manufacturing equipment. This is fueling rapid growth in the global automotive manufacturing equipment market, which is projected to see double-digit CAGR through 2030.

For OEMs and Tier 1 suppliers, embracing AI and robotics is not just a strategic advantage—it is quickly becoming a baseline requirement to stay relevant in a hyper-competitive and fast-evolving industry.

Looking Ahead

The transformation of the automotive manufacturing equipment market by AI and robotics is far from over. Emerging technologies like edge AI, 5G connectivity, and autonomous mobile robots (AMRs) are expected to further enhance production flexibility and efficiency. Meanwhile, sustainability goals are driving innovations in energy-efficient robotics and AI systems that reduce waste and emissions.

As the automotive industry moves into an era defined by electrification, automation, and digital intelligence, the integration of AI and robotics into manufacturing equipment will be the cornerstone of future growth. The factory of the future is already here—and it’s smarter, faster, and more adaptive than ever.

About MarketsandMarkets™

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ’GIVE Growth’ principle, we work with several Forbes Global 2000 B2B companies – helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103

Delray Beach, FL 33445

USA : 1-888-600-6441