As industries operate under increasing pressure to improve efficiency, reduce operational risks, and maintain the highest levels of safety, AI-driven automated Non-Destructive Testing (NDT) systems are emerging as a transformative force. Traditional inspection methods—once heavily dependent on manual techniques—are now evolving into intelligent, automated platforms capable of delivering superior accuracy, consistency, and real-time insights. This shift is redefining how companies across manufacturing, energy, transportation, aerospace, and infrastructure manage asset reliability and structural integrity.

The Rise of Intelligence in Industrial Inspection

Artificial intelligence has drastically expanded the capabilities of NDT systems. Instead of relying on human interpretation alone, automated NDT solutions now integrate machine learning models that can detect anomalies, identify patterns, and interpret complex signals with unprecedented speed. These systems learn from vast datasets, continually improving detection accuracy and reducing the risk of false positives or overlooked defects. The result is an inspection process that is both more reliable and more scalable.

AI also allows NDT systems to interpret multimodal data—from ultrasonic measurements and X-ray images to thermographic scans and acoustic signatures. Such analysis is traditionally time-consuming and prone to human error, but AI enables faster, more comprehensive assessments, helping engineers make informed decisions with greater confidence.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=233564506

Automation Enhances Precision and Consistency

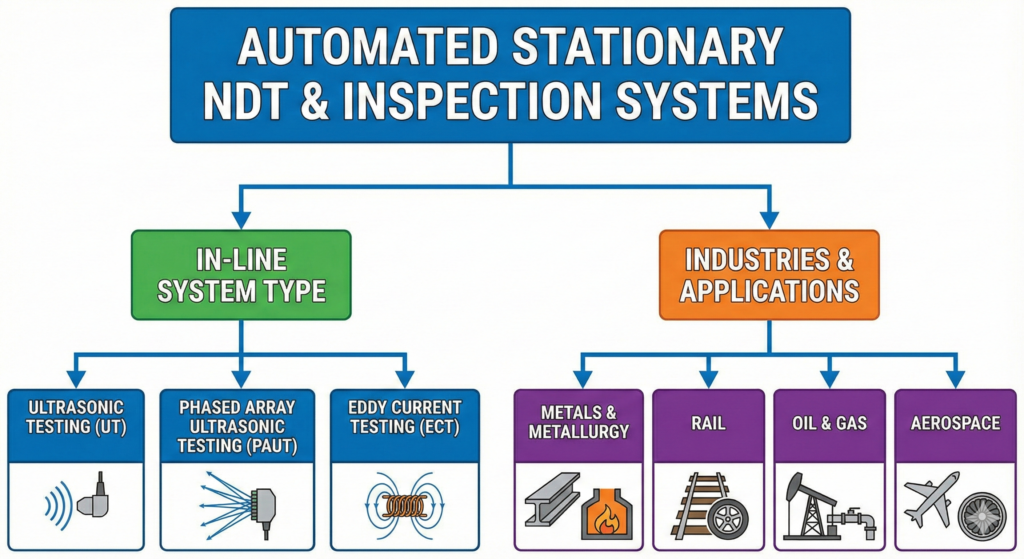

Automated stationary NDT platforms bring a new level of precision to industrial inspection processes. By removing manual variation, automated systems ensure that inspections are performed consistently, independent of operator experience or fatigue. This is particularly valuable in safety-critical industries such as aerospace and energy, where even minor defects can lead to catastrophic failures.

Robotic positioning systems, articulated arms, and automated scanning heads allow inspections to be executed with exact repeatability. These systems automatically calibrate sensors, adjust angles, and adapt scanning paths based on the geometry of the component, ensuring full coverage of even the most complex structures. This precision enhances defect detection rates, improves repeatability, and reduces rework costs.

Real-Time Monitoring and Predictive Insights

One of the most powerful benefits of AI-driven NDT is its integration into predictive maintenance strategies. Instead of detecting defects after they emerge, AI can analyze data from multiple inspection cycles to identify deterioration trends and predict future failures. This proactive approach extends asset life, reduces maintenance costs, and minimizes unplanned downtime.

Real-time data streaming and cloud connectivity allow engineers to monitor assets continuously, receiving automated alerts when anomalies develop. This creates a closed-loop feedback system where inspection data informs maintenance decisions, and operational data supports inspection refinement. Over time, these systems become more intelligent, capable of optimizing inspection intervals based on the asset’s actual condition rather than fixed schedules.

Transforming Safety Standards Across Industries

Industries with stringent safety standards are increasingly adopting AI-driven automated NDT as a foundational element of their quality assurance frameworks. Aerospace manufacturers use these systems to inspect composite structures and turbine components with extreme accuracy. Oil and gas operators rely on automated ultrasonic and radiographic inspection solutions to evaluate pipelines, pressure vessels, and critical welds. Automotive and heavy industrial manufacturers integrate automated NDT into production lines to ensure that every component meets required safety specifications before reaching the market.

This level of automation not only reduces safety risks but also supports regulatory compliance by providing detailed inspection records, traceability, and audit-ready reports.

Driving Operational Efficiency and Cost Reduction

Investing in automated AI-enabled NDT systems yields substantial long-term efficiency gains. Automated inspections are significantly faster, allowing organizations to increase throughput without sacrificing accuracy. Consistency reduces scrap and rework, improving production yield. Predictive insights reduce maintenance costs and prevent catastrophic failures that can halt operations.

Furthermore, automated NDT systems help address skilled labor shortages by reducing dependence on manual inspectors and enabling experienced technicians to focus on higher-level analysis and decision-making. Companies gain the dual advantage of resource optimization and technology-driven performance improvements.

The Path Toward Fully Autonomous Inspection

Looking ahead, the convergence of artificial intelligence, robotics, high-resolution sensors, and digital twins is paving the way for fully autonomous inspection environments. Future systems will not only detect and diagnose defects but also adjust processes, recommend corrective actions, and synchronize with broader industrial automation platforms.

The vision is an integrated ecosystem where inspection is embedded seamlessly into manufacturing, maintenance, and asset-management workflows—creating a continuous, intelligent safety and reliability framework.

AI-driven automated NDT systems are fundamentally reshaping industrial safety and reliability. By combining advanced sensing technologies with intelligent analytics and automated workflows, these systems deliver unparalleled accuracy, efficiency, and predictive capability. As industries face increasing complexity and higher expectations for safety and uptime, AI-enabled inspection will become a cornerstone of modern industrial strategy. The companies that embrace these technologies early will gain a significant competitive advantage in performance, cost savings, and long-term operational resilience.

FAQ: AI-Driven Automated NDT Systems

1. What are AI-driven automated NDT systems?

AI-driven automated Non-Destructive Testing (NDT) systems combine advanced sensors, robotics, imaging technologies, and artificial intelligence to inspect materials and components without causing damage. They automate the entire inspection workflow—scanning, defect detection, analysis, and reporting—while improving accuracy and consistency.

2. How does AI enhance NDT performance?

AI algorithms analyze inspection data to detect patterns and anomalies that may be difficult or impossible for human inspectors to identify. Machine learning models improve over time, increasing detection accuracy and reducing false positives. AI also enables rapid interpretation of complex signals from ultrasonic, radiographic, thermographic, and acoustic monitoring systems.

3. Which industries benefit most from AI-driven NDT?

Industries with high safety, reliability, and compliance demands—such as aerospace, automotive, oil & gas, power generation, heavy manufacturing, rail, and infrastructure—gain the greatest benefits. These sectors require precise, repeatable inspections to identify micro-defects, structural weaknesses, weld inconsistencies, and material fatigue.

4. What advantages do automated stationary NDT systems offer?

Automated stationary systems provide higher precision, repeatability, and scanning speed than manual methods. They ensure consistent inspection quality, eliminate human variability, and offer full-coverage inspection of complex geometries. These systems also integrate with production lines for continuous quality monitoring.

5. Can AI-driven NDT systems reduce operational costs?

Yes. Automation reduces labor requirements, minimizes rework, cuts downtime by detecting issues earlier, and extends asset life through proactive maintenance insights. Predictive analytics prevent costly failures, while automated workflows shorten inspection cycles—delivering long-term cost savings.

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America’s Best Management Consulting Firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. With the widest lens on emerging technologies, we are proficient in co-creating supernormal growth for clients across the globe.

Today, 80% of Fortune 2000 companies rely on MarketsandMarkets, and 90 of the top 100 companies in each sector trust us to accelerate their revenue growth. With a global clientele of over 13,000 organizations, we help businesses thrive in a disruptive ecosystem.

The B2B economy is witnessing the emergence of $25 trillion in new revenue streams that are replacing existing ones within this decade. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ‘GIVE Growth’ principle, we collaborate with several Forbes Global 2000 B2B companies to keep them future-ready. Our insights and strategies are powered by industry experts, cutting-edge AI, and our Market Intelligence Cloud, KnowledgeStore™, which integrates research and provides ecosystem-wide visibility into revenue shifts.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter , LinkedIn and Facebook .

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103, Delray Beach, FL 33445

USA: +1-888-600-6441

Visit Our Website: https://www.marketsandmarkets.com/