The question of How Fast Is the 3D Printing Market Growing Across Manufacturing and Healthcare Industries is pivotal as industries worldwide embrace additive manufacturing to revolutionize production and innovation. 3D printing, also known as additive manufacturing, has transitioned from a niche technology to a cornerstone of modern manufacturing and healthcare. Its ability to create complex, customized, and cost-effective solutions has fueled rapid adoption, driving significant market expansion. This article delves into the growth trajectory of the 3D printing market, exploring its impact on manufacturing and healthcare, key drivers, challenges, and future potential, while providing a detailed analysis of market trends, statistics, and applications.

Understanding the Evolution and Importance of 3D Printing Technology in Modern Industries

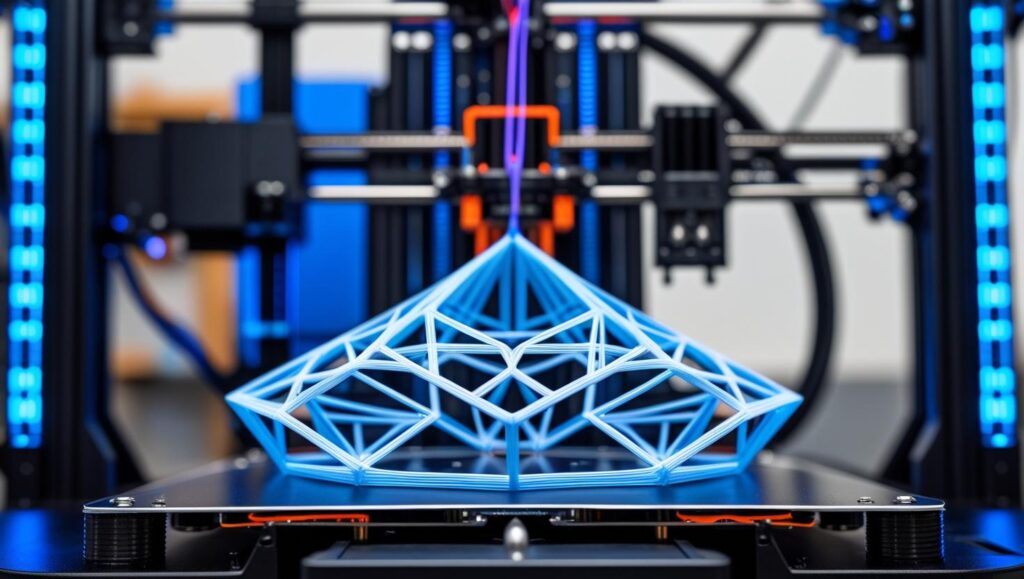

3D printing technology has evolved dramatically since its inception in the 1980s, moving from rudimentary prototyping tools to sophisticated systems capable of producing intricate components for industrial and medical applications. In manufacturing, it enables rapid prototyping, reduces material waste, and supports the creation of complex geometries that traditional methods cannot achieve. In healthcare, 3D printing is transforming patient care by enabling personalized medical devices, implants, and even bioprinted tissues. The versatility of this technology has made it a game-changer, with industries leveraging its potential to enhance efficiency, reduce costs, and drive innovation. The rapid growth of the 3D printing market reflects its increasing integration into these sectors, fueled by advancements in materials, software, and printing techniques.

Current Market Size and Growth Projections for 3D Printing in Manufacturing and Healthcare

The global 3D printing market has experienced remarkable growth, with its value projected to soar in the coming years. The global 3D Printing market size is projected to reach approximately USD 19.2 billion in 2025, growing from USD 17.5 billion in 2024 To USD 37.4 billion by 2029, at a CAGR of 16.4% during the forecast period from 2024 to 2029. This growth is driven by increasing adoption in manufacturing for applications like aerospace components, automotive parts, and consumer goods, as well as in healthcare for prosthetics, implants, and surgical planning tools. The question of How Fast Is the 3D Printing Market Growing Across Manufacturing and Healthcare Industries is answered by these robust figures, which highlight the technology’s transformative impact. The market’s expansion is supported by technological advancements, declining costs of 3D printers, and growing demand for customized solutions.

Key Drivers Fueling the Rapid Expansion of 3D Printing in Manufacturing Processes

Several factors are propelling the rapid growth of 3D printing in manufacturing. First, the technology’s ability to streamline production processes by reducing lead times and enabling on-demand manufacturing is a significant driver. Manufacturers can produce parts directly from digital designs, eliminating the need for extensive tooling and reducing inventory costs. Additionally, 3D printing supports sustainability by minimizing material waste compared to subtractive manufacturing methods. The aerospace industry, for instance, uses 3D printing to create lightweight components that improve fuel efficiency, while automotive manufacturers leverage it for rapid prototyping and customized parts. The flexibility to use diverse materials, such as metals, plastics, and composites, further enhances its appeal, making it a vital tool for modern manufacturing.

Transformative Applications of 3D Printing in the Healthcare Sector

In healthcare, 3D printing is revolutionizing patient care and medical innovation. The technology enables the production of patient-specific implants, such as dental crowns, hip replacements, and cranial plates, tailored to individual anatomies. It also supports the creation of surgical guides, which improve precision during complex procedures. Bioprinting, an emerging field, uses 3D printing to create tissue-like structures, offering potential for organ regeneration and drug testing. The ability to produce low-cost prosthetics has also democratized access to life-changing medical devices, particularly in underserved regions. These applications underscore why How Fast Is the 3D Printing Market Growing Across Manufacturing and Healthcare Industries is a critical question, as healthcare continues to adopt additive manufacturing at an unprecedented pace.

Technological Advancements Accelerating 3D Printing Market Growth Across Industries

Technological innovations are a cornerstone of the 3D printing market’s rapid expansion. Improvements in printer speed, precision, and material compatibility have broadened the technology’s applications. For example, advancements in metal 3D printing, such as selective laser melting (SLM) and direct metal laser sintering (DMLS), have enabled the production of high-strength components for aerospace and automotive industries. In healthcare, developments in biocompatible materials and multi-material printing have enhanced the production of complex medical devices. Software improvements, including AI-driven design optimization and cloud-based platforms, have also streamlined workflows, making 3D printing more accessible and efficient. These advancements are key to answering How Fast Is the 3D Printing Market Growing Across Manufacturing and Healthcare Industries, as they drive adoption and scalability.

Regional Insights into the Global 3D Printing Market Expansion Trends

The growth of the 3D printing market varies by region, with North America, Europe, and Asia-Pacific leading the charge. North America, particularly the United States, dominates due to its strong industrial base, significant R&D investments, and early adoption of additive manufacturing. Europe follows closely, with countries like Germany and the UK leveraging 3D printing for automotive and aerospace applications. Asia-Pacific, driven by China and Japan, is experiencing rapid growth due to increasing industrialization and government support for advanced manufacturing. Emerging markets in Latin America and the Middle East are also beginning to adopt 3D printing, particularly in healthcare, as costs decline and awareness grows. These regional dynamics highlight the global scope of the 3D printing market’s expansion.

Challenges and Barriers to Sustained 3D Printing Market Growth

Despite its rapid growth, the 3D printing market faces several challenges. High initial costs for advanced 3D printers and materials can be a barrier, particularly for small and medium-sized enterprises. Additionally, the lack of standardized processes and regulations, especially in healthcare, can hinder adoption. Intellectual property concerns also arise, as 3D printing makes it easier to replicate designs. In manufacturing, limitations in production speed and scalability for large-scale applications remain a hurdle. However, ongoing innovations, such as faster printing technologies and more affordable materials, are addressing these challenges, ensuring that the market continues to grow despite these obstacles.

Opportunities for Future Growth in 3D Printing Across Manufacturing and Healthcare

The future of 3D printing is brimming with opportunities. In manufacturing, the rise of Industry 4.0 and smart factories is integrating 3D printing with automation, IoT, and AI, creating more efficient production systems. The development of new materials, such as high-performance polymers and advanced composites, will expand applications in industries like aerospace and energy. In healthcare, bioprinting holds immense potential for creating functional organs, potentially addressing the global organ shortage. Additionally, the increasing focus on sustainability is driving demand for 3D printing, as it reduces waste and supports localized production. These opportunities position 3D printing as a key driver of innovation in both sectors.

Industry-Specific Case Studies Highlighting 3D Printing’s Impact and Growth Potential

Real-world examples illustrate the transformative power of 3D printing. In manufacturing, companies like General Electric (GE) have used 3D printing to produce complex jet engine components, reducing weight and improving fuel efficiency. In healthcare, firms like Stryker leverage 3D printing to create patient-specific spinal implants, improving surgical outcomes. Non-profits like e-NABLE use 3D printing to produce affordable prosthetic limbs for children, showcasing its social impact. These case studies demonstrate why How Fast Is the 3D Printing Market Growing Across Manufacturing and Healthcare Industries is a question with far-reaching implications, as the technology continues to reshape industries and lives.

The Role of Government and Private Sector Investments in Driving Market Expansion

Government and private sector investments are critical to the 3D printing market’s growth. Governments in the U.S., China, and Europe are funding research and development to advance additive manufacturing technologies. For example, the U.S. Department of Defense has invested in 3D printing for military applications, while the European Union supports initiatives to integrate 3D printing into manufacturing. Private companies, including startups and established firms like HP and Stratasys, are also driving innovation through R&D and strategic partnerships. These investments are accelerating the development of new materials, printers, and applications, ensuring sustained market growth.

Sustainability and Cost Efficiency as Catalysts for 3D Printing Adoption

Sustainability and cost efficiency are major factors driving 3D printing adoption. Unlike traditional manufacturing, which often involves significant material waste, 3D printing builds objects layer by layer, using only the necessary materials. This reduces waste and lowers production costs, particularly for small-batch or customized products. In healthcare, 3D printing reduces the cost of producing custom medical devices, making them more accessible. The ability to produce parts locally also minimizes transportation costs and carbon emissions, aligning with global sustainability goals. These benefits make 3D printing an attractive solution for environmentally conscious industries.

The Impact of 3D Printing on Supply Chain Optimization and Resilience

3D printing is transforming supply chains by enabling on-demand production and reducing reliance on global sourcing. During the COVID-19 pandemic, 3D printing played a critical role in addressing supply chain disruptions by producing essential items like ventilator parts and personal protective equipment (PPE). In manufacturing, companies are using 3D printing to create spare parts on-site, reducing downtime and inventory costs. In healthcare, localized production of medical devices ensures faster delivery to patients. This shift toward decentralized manufacturing enhances supply chain resilience, further driving the adoption of 3D printing across industries.

Emerging Trends Shaping the Future of the 3D Printing Market

Several emerging trends are shaping the future of the 3D printing market. The integration of 3D printing with digital twins and IoT is enabling real-time monitoring and optimization of manufacturing processes. In healthcare, the development of 4D printing, which involves materials that change shape over time, is opening new possibilities for adaptive medical devices. The rise of cloud-based 3D printing platforms is also democratizing access to the technology, allowing smaller businesses to leverage advanced systems. These trends underscore the dynamic nature of the 3D printing market and its potential for continued growth.

Competitive Landscape and Key Players in the 3D Printing Industry

The 3D printing market is highly competitive, with key players driving innovation and market expansion. Companies like Stratasys, 3D Systems, and HP dominate the industrial 3D printing space, offering advanced printers and materials. In healthcare, firms like Materialise and Formlabs are leading the way in medical-grade 3D printing solutions. Startups like Desktop Metal and Carbon are also making waves with innovative technologies like metal binder jetting and digital light synthesis. This competitive landscape fosters continuous innovation, ensuring that the market remains dynamic and responsive to industry needs.

How Fast Is the 3D Printing Market Growing Across Manufacturing and Healthcare Industries

To directly address How Fast Is the 3D Printing Market Growing Across Manufacturing and Healthcare Industries, the market is expanding at a robust CAGR of over 20%, driven by technological advancements, increasing demand for customization, and cost efficiencies. In manufacturing, the adoption of 3D printing for prototyping, production, and supply chain optimization is fueling growth, while in healthcare, applications like bioprinting and patient-specific devices are driving rapid adoption.

Explore In-Depth Semiconductor & Electronics Market Research –https://www.marketsandmarkets.com/semiconductorand-electonics-market-research-87.html

FAQs

What is driving the growth of the 3D printing market in manufacturing and healthcare?

The growth is driven by advancements in technology, cost efficiencies, customization capabilities, and increasing demand for sustainable and on-demand production solutions.

How is 3D printing used in the healthcare industry?

3D printing is used to create patient-specific implants, prosthetics, surgical guides, and bioprinted tissues, improving precision and accessibility in healthcare.

What challenges does the 3D printing market face?

Challenges include high initial costs, lack of standardization, intellectual property concerns, and limitations in production speed and scalability.

Which regions are leading the 3D printing market growth?

North America, Europe, and Asia-Pacific are leading, with the U.S., Germany, China, and Japan driving significant adoption in manufacturing and healthcare.

See The Latest Semiconductor Reports:

Biosensors Market Size, Share & Trends 2025 To 2030 :

https://www.marketsandmarkets.com/Market-Reports/biosensors-market-798.html

Building Automation System Market Size, Share & Trends, 2025 To 2030 :

https://www.marketsandmarkets.com/Market-Reports/building-automation-control-systems-market-408.html

Precision Farming Market Size, Share & Trends, 2025 To 2032 :

https://www.marketsandmarkets.com/Market-Reports/precision-farming-market-1243.html