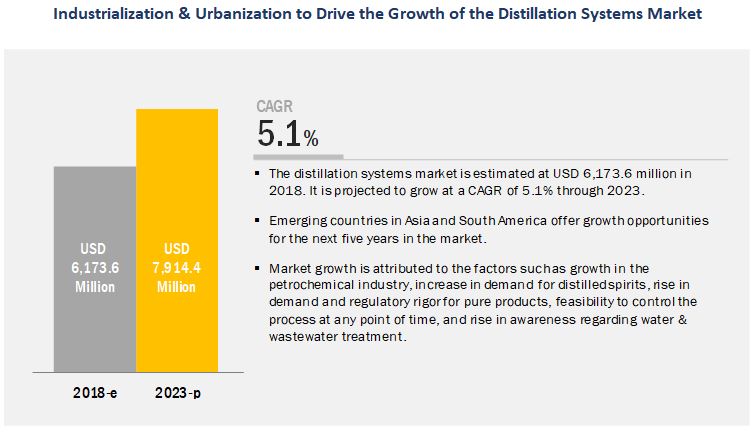

The distillation systems market was valued at USD 5.94 billion in 2017; it is projected to grow at a CAGR of 5.1%, to reach USD 7.91 billion by 2023.

Factors such as growing industrialization and urbanization have significantly fueled the market growth of distillation systems for various industrial applications. Increasing urbanization leads to a surge in demand for water treatment systems and products from the oil & gas, food & beverage, healthcare, and manufacturing industries. Imposition of regulations and rise in the demand for pure products including water is projected to fuel the demand for the distillation systems. On the account of these factors, the global market is projected to witness significant growth during the forecast period.

The distillation systems market, based on components, is segmented into column shells, plates & packings, reboilers & heaters, condenser, and others. The column shells segment is estimated to dominate the market with the largest share in 2018 due to the high cost of the components. This is followed by the plates & packings segment, as these are consumable components in the distillation systems and are used largely across industries.

The market, based on technique, is segmented into fractional, steam, vacuum, multiple-effect (MED), and others. The vacuum segment is projected to grow at the highest CAGR among all distillation techniques from 2018 to 2023. The technique is widely used for the separation of components, where chances of decomposition are high due to change in temperature and pressure. Vacuum distillation is commonly used for the separation of heavy hydrocarbon residues that are left during the atmospheric distillation of crude oil.

The key players are GEA (Germany), Alfa Laval (Sweden), SPX FLOW (US), Sulzer (Switzerland), Core Laboratories (Netherlands), PILODIST (Germany), Anton Paar (Austria), Praj Industries (India), L&T Hydrocarbon Engineering (India), EPIC Modular Process Systems (US), BÜFA Composite System (Germany), and Bosch Packaging Technology (Germany).