As consumer demand accelerates for smarter, smaller, and more powerful electronic devices, manufacturers are under increasing pressure to produce highly complex circuit boards with unmatched speed and accuracy. At the heart of this transformation is Surface Mount Technology (SMT)—a method that has become the backbone of modern electronics assembly. With the rise of next-generation technologies such as AI, IoT, 5G, and autonomous systems, next-gen SMT solutions are enabling manufacturers to meet today’s manufacturing challenges head-on while laying the foundation for tomorrow’s innovations.

What is Next-Gen SMT?

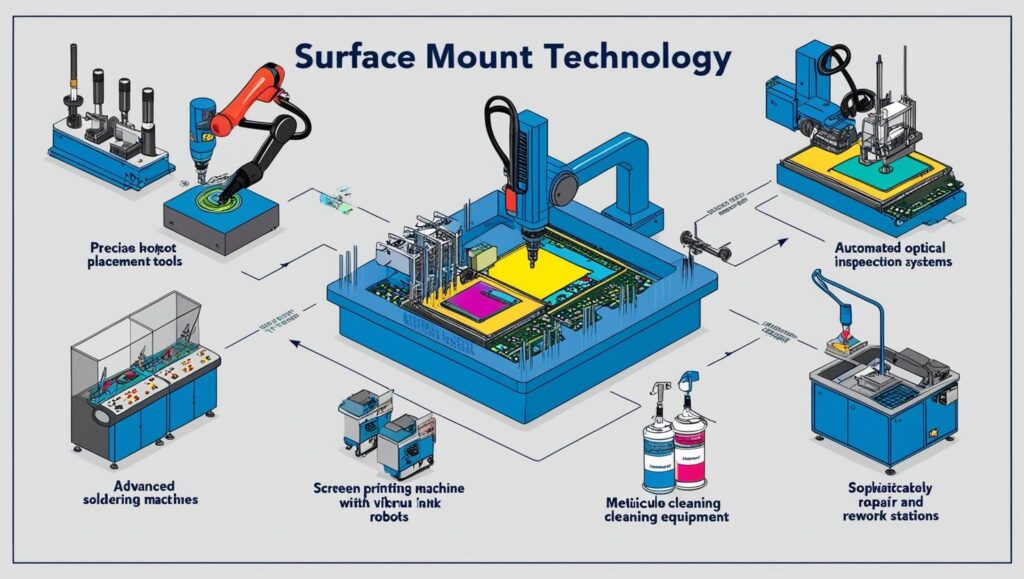

Next-gen Surface Mount Technology refers to advanced SMT systems that integrate automation, real-time monitoring, AI-driven optimization, and ultra-precise component placement. These systems are designed to assemble high-density printed circuit boards (PCBs) at speeds and tolerances far beyond the capabilities of traditional methods.

Unlike earlier SMT processes, next-gen SMT equipment incorporates high-speed pick-and-place machines, 3D optical inspection (AOI), automated solder paste printing, and smart feeders to handle miniaturized components—many of which are smaller than a grain of rice. These capabilities allow manufacturers to produce increasingly complex devices such as smartphones, wearables, automotive ECUs, and medical implants with higher yields and fewer defects.

The surface mount technology (SMT) industry is projected to grow from USD 5.8 billion in 2023 to reach USD 8.4 billion by 2028; it is expected to grow at a CAGR of 7.8% during the forecast period. Some of the major driving factors for the growth of this market include the increased demand for miniaturized consumer electronics products and the increasing adoption of electric vehicles.

Driving Forces Behind SMT Advancements

Miniaturization and High Component Density

Modern electronic devices demand more functionality in smaller spaces. Components such as microprocessors, MEMS sensors, and RF modules now occupy minimal PCB real estate. Next-gen SMT systems use ultra-fine placement heads, vision-based alignment, and real-time corrections to ensure accurate mounting, even on densely packed boards.

Industry 4.0 Integration

The digital transformation of manufacturing, known as Industry 4.0, is having a profound impact on SMT. By leveraging AI algorithms, data analytics, and IoT connectivity, SMT lines can now self-calibrate, predict maintenance needs, and optimize workflows dynamically. These capabilities not only reduce downtime but also enhance production flexibility—crucial in a market defined by rapid design cycles and mass customization.

Quality Assurance Through Advanced Inspection

Next-gen SMT places a premium on quality and reliability. 3D automated optical inspection (3D AOI) and X-ray inspection systems are standard components of modern SMT lines, providing real-time feedback on solder quality, alignment accuracy, and component integrity. This ensures that defects are identified early in the process, reducing waste and rework costs.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=99662691

Applications Across High-Growth Sectors

Consumer Electronics

From smartphones and tablets to gaming consoles and smart home devices, SMT enables manufacturers to produce compact, high-performance products at scale. Speed and precision are especially critical here, where product cycles are short and design complexity is high.

Automotive Electronics

The automotive industry, with its shift toward electric and autonomous vehicles, is heavily reliant on advanced SMT for the production of control units, sensors, infotainment systems, and ADAS modules. These systems demand high reliability and tolerance to harsh environments, which modern SMT lines are designed to accommodate.

Medical Devices

In the medical field, SMT is used to assemble life-critical devices such as pacemakers, diagnostic equipment, and wearable health monitors. Regulatory requirements demand extremely low defect rates and traceable manufacturing processes—capabilities well supported by next-gen SMT platforms.

Industrial Automation & 5G Infrastructure

As factories modernize and 5G networks expand, the need for high-speed, reliable electronics is growing. SMT supports the production of communication modules, edge computing systems, and robotic control units that power the next generation of connected infrastructure.

Challenges and Outlook

While the benefits are clear, challenges such as component shortages, rising equipment costs, and the need for skilled operators persist. However, with growing investments in automation, training, and supply chain resilience, the SMT industry is well-positioned to address these issues.

Looking ahead, innovations in AI-based defect detection, machine learning-driven predictive maintenance, and fully autonomous SMT lines will further enhance efficiency and accuracy. These developments are expected to reduce production costs and speed up time-to-market, giving manufacturers a critical edge in an increasingly competitive global landscape.

Next-generation Surface Mount Technology is no longer just a production method—it’s a strategic asset driving the future of electronics manufacturing. By enabling high-speed, precision assembly of increasingly complex components, SMT is playing a pivotal role in shaping innovations across industries. As global demand for connected, compact, and intelligent devices continues to rise, SMT will remain the cornerstone of scalable, efficient, and reliable electronics production.

About MarketsandMarkets™

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ’GIVE Growth’ principle, we work with several Forbes Global 2000 B2B companies – helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103

Delray Beach, FL 33445

USA : 1-888-600-6441