As industries across the globe push for energy efficiency, compact solutions, and easy maintenance, Plate & Frame Heat Exchangers (PHEs) have emerged as the go-to technology in thermal exchange systems. These versatile units are engineered to transfer heat between two fluids without mixing them—making them ideal for applications in power plants, food processing, chemical refineries, HVAC systems, and more.

Unlike traditional shell-and-tube exchangers, PHEs are designed with a series of corrugated metal plates that create turbulence and maximize surface area. This translates to superior heat transfer, smaller footprints, and easy scalability, making PHEs a smart investment for both retrofit projects and new plant builds.

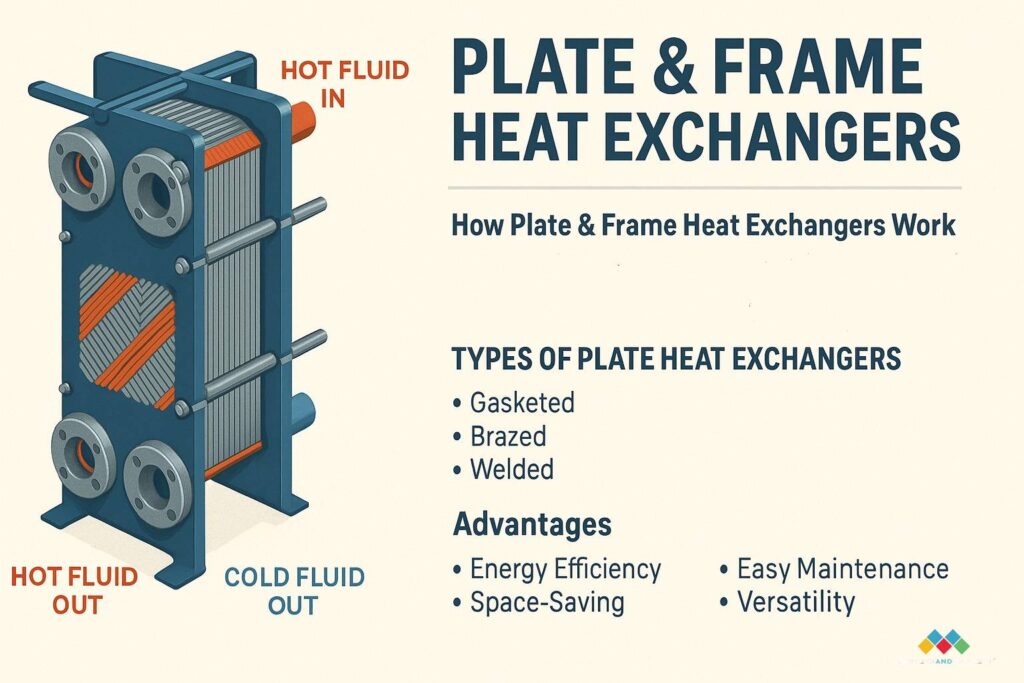

How Plate & Frame Heat Exchangers Work

The construction of a PHE involves multiple thin plates—usually made of stainless steel or titanium—arranged in a frame with gaskets or brazing. Fluids flow in alternating channels, with hot and cold streams separated by each plate. The corrugation of the plates induces turbulent flow even at low Reynolds numbers, dramatically enhancing heat transfer efficiency while reducing fouling and pressure drop.

There are three common types of plate heat exchangers:

- Gasketed Plate Heat Exchangers – Ideal for processes requiring frequent cleaning or flexible operation.

- Brazed Plate Heat Exchangers – Compact and maintenance-free, commonly used in HVAC and refrigeration.

- Welded Plate Heat Exchangers – Suitable for high-pressure and high-temperature applications where gaskets are unsuitable.

Market Growth and Industry Trends

The global Plate & Frame Heat Exchangers Market is projected to grow significantly, driven by decarbonization goals, rising energy costs, and demand for clean energy technologies. The market is expected to reach USD 10.50 billion by 2030, growing at a CAGR of 7.8% during the forecast period.

Key market trends include:

- Shift toward renewable energy integration – PHEs are essential in geothermal and solar thermal systems for efficient heat recovery.

- Growth in food & beverage processing – Hygienic design and CIP (Clean-In-Place) compatibility make PHEs crucial for pasteurization, brewing, and dairy processing.

- Expansion of district heating & cooling networks – Particularly in Europe and Asia, where governments are investing in sustainable urban infrastructure.

- Rising demand for modularity – Manufacturers and utilities prefer solutions that are easy to expand or service without major system downtime.

Leading Manufacturers and Innovations

Several global players dominate the Plate & Frame Heat Exchangers landscape, each bringing specialized solutions and cutting-edge R&D:

- Alfa Laval (Sweden) – A pioneer in thermal technology, offering gasketed, brazed, and fusion-bonded PHEs for nearly every industry.

- GEA Group (Germany) – Known for hygienic PHEs and energy-saving designs tailored to food, pharma, and marine sectors.

- SPX FLOW (US) – Offers industrial PHEs with robust construction and easy maintenance for oil & gas and power sectors.

- SWEP (Sweden) – Focused on compact, brazed PHEs for HVAC, refrigeration, and district energy markets.

- Danfoss (Denmark) – Provides energy-efficient PHEs designed for heat pumps and commercial building systems.

These companies are investing heavily in digital monitoring, anti-corrosion materials, and modular designs to future-proof their offerings.

Why Industry Experts Prefer Plate & Frame Designs

From a procurement and operational perspective, Plate & Frame Heat Exchangers offer several compelling advantages:

- Energy Efficiency: The turbulent flow and large surface area minimize thermal resistance, leading to superior energy savings.

- Space-Saving: Their compact structure allows installation in tight spaces—a huge benefit in retrofitting legacy systems.

- Easy Maintenance: Gasketed models can be disassembled quickly, reducing downtime and cleaning costs.

- Versatility: Compatible with a wide range of fluids, temperatures, and pressures, making them ideal for multipurpose facilities.

- Sustainability: Many PHEs today are optimized for low-GWP refrigerants and contribute to LEED-certified building designs.

For plant engineers and systems integrators, these benefits translate into long-term operational cost savings and improved process control.

The Plate & Frame Heat Exchangers market is experiencing a resurgence as industries embrace smarter, cleaner, and more efficient thermal systems. Whether you’re modernizing an HVAC system, expanding a food processing line, or scaling an energy-intensive operation, PHEs provide a high-performance, low-footprint solution backed by decades of engineering refinement.

As global energy goals evolve, so does the role of heat exchangers. Partnering with innovative PHE manufacturers will be critical in ensuring not just operational efficiency, but also environmental responsibility.