The era of intelligent automation is here, and at the heart of this revolution are smart encoders—precision devices that are transforming how industries monitor, control, and optimize motion systems. With growing demands for accuracy, real-time data, and system integration, smart encoders are playing a pivotal role in reshaping the industrial automation landscape.

What Are Smart Encoders?

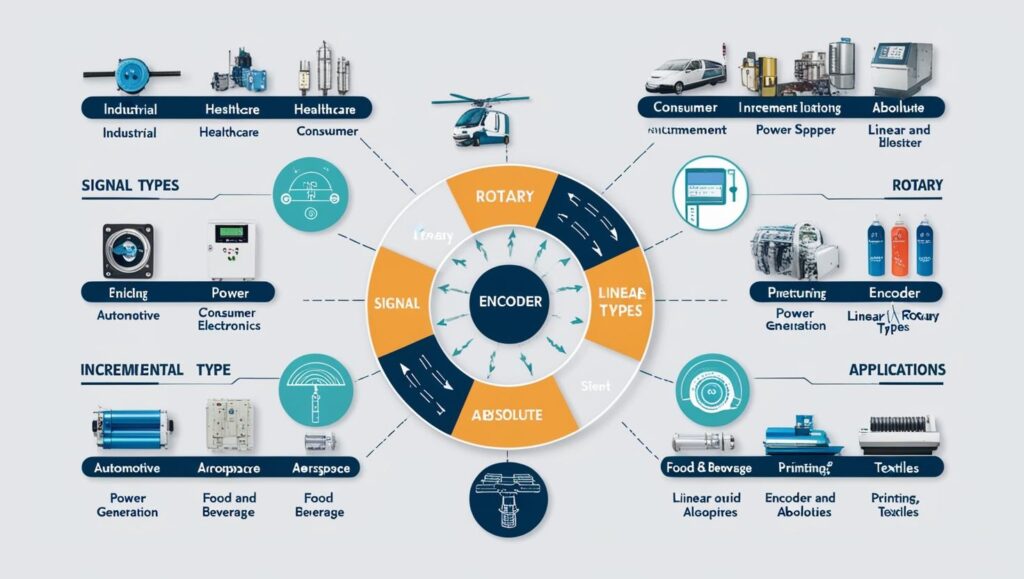

Smart encoders are advanced motion-sensing devices that go beyond basic position and speed feedback. Unlike traditional encoders, they incorporate integrated electronics, communication interfaces, and data processing capabilities. This allows them to interact with programmable logic controllers (PLCs), industrial networks, and cloud platforms—delivering actionable insights for predictive maintenance and performance optimization.

As factories embrace digital transformation and Industry 4.0, smart encoders have become essential for high-performance automation systems, including robotics, CNC machinery, packaging lines, and conveyor systems.

Key Benefits of Smart Encoders in Automation

- The adoption of smart encoders in industrial settings brings numerous advantages:

- Real-Time Data Transmission: Smart encoders provide instant feedback on position, velocity, and direction, enabling precise machine control.

- Enhanced Diagnostics: Built-in health monitoring features allow early detection of wear, misalignment, or potential failure.

- Easy Integration: They support a variety of communication protocols such as EtherCAT, PROFINET, and IO-Link, making them suitable for complex industrial networks.

- Reduced Downtime: Through predictive maintenance and system alerts, smart encoders help reduce unexpected machine failures and improve operational efficiency.

- These benefits make smart encoders a cornerstone in achieving automation goals such as increased productivity, safety, and cost savings.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=14566162

Market Growth Driven by Innovation

The global demand for smart encoders is growing rapidly as industries shift toward intelligent, connected systems. Key sectors fueling this growth include:

- Automotive Manufacturing: For precise assembly and motion control.

- Electronics: In high-speed pick-and-place and PCB production lines.

- Packaging and Logistics: Where speed, flexibility, and real-time tracking are crucial.

- Renewable Energy: Especially in wind turbines and solar tracking systems that require accurate positional data.

With continued innovation in miniaturization, wireless communication, and edge computing, smart encoders are expected to penetrate even more industries in the coming years.

Challenges and Opportunities

While the benefits of smart encoders are clear, some challenges remain:

- Initial Cost: Smart encoders are more expensive than traditional models, though the return on investment (ROI) is often realized through increased uptime and efficiency.

- Compatibility: Ensuring seamless integration with legacy systems can be complex.

- Cybersecurity: As smart devices become network-connected, they also become targets for cyber threats.

However, these challenges also present opportunities for innovation in secure communication protocols, plug-and-play interfaces, and software integration tools.

The Future of Smart Encoders

Looking forward, smart encoders will continue to evolve with advancements in AI, machine learning, and edge computing. Next-generation encoders will likely feature self-configuration, automated calibration, and more robust data analytics—all aimed at enabling fully autonomous and adaptive industrial systems.

Moreover, as 5G and industrial IoT (IIoT) infrastructure expand, smart encoders will become even more powerful in supporting real-time, decentralized decision-making across factory floors and global supply chains.

Smart encoders are not just incremental upgrades—they represent a fundamental shift in how industrial automation systems operate. By providing high-resolution feedback, self-diagnostics, and intelligent connectivity, smart encoders are driving the next wave of industrial efficiency and innovation.

As factories become smarter and more connected, smart encoders will remain a critical technology shaping the future of industrial automation worldwide.

Frequently Asked Questions (FAQ)

1. What are smart encoders?

Smart encoders are advanced motion-sensing devices that not only track position, speed, and direction but also provide real-time data, diagnostics, and connectivity to industrial networks. They are a key component in modern automation systems, offering more functionality than traditional encoders.

2. How do smart encoders differ from traditional encoders?

Unlike traditional encoders, smart encoders include onboard processing, communication protocols (e.g., PROFINET, EtherCAT, IO-Link), and diagnostics capabilities. This enables predictive maintenance, faster response times, and better integration with smart factory environments.

3. Why are smart encoders important in industrial automation?

Smart encoders enable precise control and real-time feedback in automated systems. They support enhanced efficiency, reduced downtime, and improved product quality—making them essential in industries like robotics, automotive, packaging, and electronics.

4. Which industries are driving demand for smart encoders?

Key industries adopting smart encoders include:

- Automotive manufacturing

- Robotics and CNC machinery

- Packaging and logistics

- Renewable energy

- Semiconductors and electronics