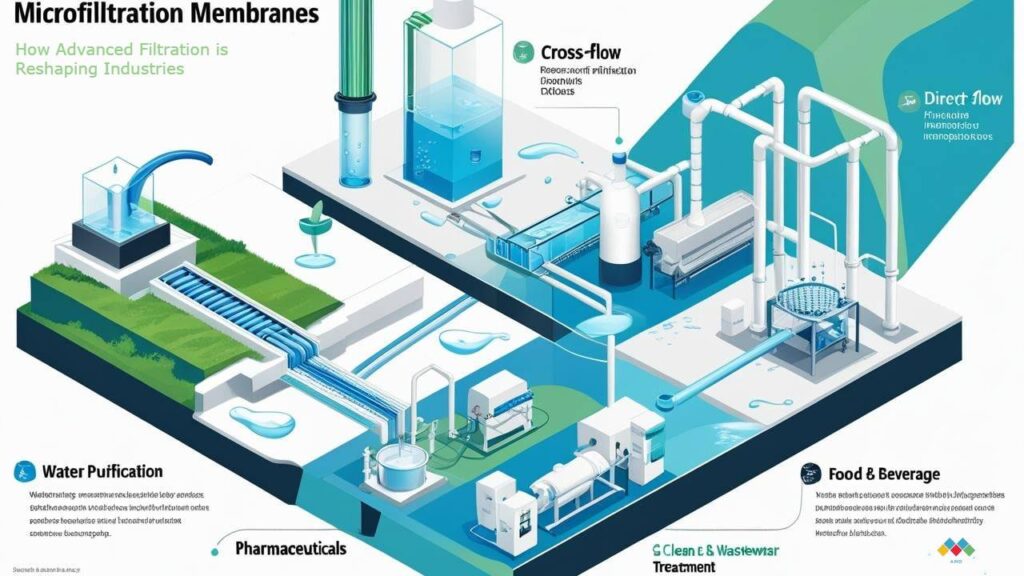

In today’s fast-evolving industrial landscape,a growing sector, renowned for its ability to precisely separate microscopic particles, bacteria, and suspended solids from liquids. This technology is indispensable across critical applications, including water purification, food and beverage processing, and pharmaceutical manufacturing, where high standards of clarity and sterility are paramount. Driven by increasing global demands for clean water, product quality, and sustainable industrial solutions, the Microfiltration Membranes Industry is experiencing robust growth and continuous innovation, positioning itself as a key enabler for numerous essential processes worldwide.

This isn’t just an incremental upgrade; it’s a membrane revolution. These sophisticated technologies are redefining what’s possible in separation and purification, offering precision, efficiency, and environmental benefits that were once thought unattainable. From ensuring safe drinking water to crafting high-quality pharmaceuticals, advanced filtration is proving to be an indispensable tool, driving innovation across the globe.

What is Advanced Membrane Filtration?

At its core, advanced membrane filtration involves using selective barriers – membranes – to separate substances. Unlike traditional filters that simply block particles, membranes operate at a molecular level, allowing specific molecules to pass through while retaining others based on size, charge, or other properties.

This distinction is crucial. While conventional filtration often relies on depth or surface capture, membrane technology employs incredibly fine, porous or non-porous barriers. This enables continuous operation, significantly finer separation, and often a reduced need for chemical additives. We’re talking about a spectrum of technologies, from microfiltration (removing particles and bacteria) to ultrafiltration (removing viruses and larger proteins), nanofiltration (removing salts and organic molecules), and the ultra-fine precision of reverse osmosis (removing nearly all dissolved solids). Each type offers a progressive level of selectivity, collectively forming a powerful toolkit for diverse industrial challenges. Their key characteristics include high selectivity, remarkable energy efficiency, and scalability, making them suitable for operations of all sizes.

Download PDF Brochure – Get in-depth insights, market segmentation, and technology trends

Reshaping Key Industries: Case Studies & Impact

The real power of the membrane revolution is best seen in its transformative impact across various sectors:

A. Water & Wastewater Treatment: The Purity Paradigm

Historically, water treatment has grappled with the challenges of chemical use, sludge generation, and vast land footprints. Advanced membrane filtration is changing this narrative. By physically removing contaminants, membranes enable the purification of challenging water sources into potable water and facilitate advanced wastewater reuse. This significantly reduces reliance on harsh chemicals, minimizes waste, and allows for more compact treatment facilities. The impact is profound: membranes are becoming a cornerstone in addressing global water scarcity, enabling industries to recycle their water, and helping nations meet increasingly stringent environmental discharge regulations.

Food & Beverage: Enhancing Quality and Efficiency

In the food and beverage industry, clarity, sterility, and ingredient integrity are paramount. Traditional methods often involved heat treatment or extensive filtration steps that could compromise product quality or consume significant energy. Membrane filtration steps in to offer precise solutions for clarification of juices, sterile filtration of milk without excessive heat (extending shelf life), and the concentration of valuable proteins (like whey protein) from dairy streams. This leads to products with cleaner labels, enhanced taste and nutritional profiles, and a more energy-efficient production process, opening doors for innovative new food and beverage products.

Pharmaceuticals & Biotechnology: Precision and Safety

The pharmaceutical and biotechnology sectors demand the highest levels of purity and sterility. Here, advanced membranes are indispensable. They are used for sterile filtration of drug products, removal of viruses from biological solutions, precise concentration of sensitive biomolecules (like enzymes and antibodies), and efficient harvesting of cells in fermentation processes. This precision ensures the safety and efficacy of critical medicines, accelerates drug development timelines, and optimizes bioprocessing workflows, directly contributing to advancements in healthcare.

Industrial & Chemical Processing: Optimizing Operations

From heavy industry to specialized chemical manufacturing, waste streams, resource recovery, and energy-intensive separations have long been significant concerns. Membrane technology provides powerful solutions for recovering valuable solvents, separating gases for industrial applications, and treating complex effluents to meet environmental standards or enable water reuse. The direct impact is a dramatic reduction in waste generation, increased resource efficiency, lower operational costs due to less energy consumption, and robust compliance with ever-tightening emission regulations, making industrial operations cleaner and more profitable.

The Future of Advanced Filtration

The membrane revolution is far from over. The future promises even more sophisticated solutions, with ongoing innovations in smart membranes that can self-clean or respond to stimuli, and the development of new, highly durable materials. This continuous evolution further enhances their efficiency and expands their applicability.

Crucially, advanced membrane filtration stands as a pillar of sustainability. By facilitating water reuse, recovering valuable resources from waste streams, and enabling more energy-efficient separations, it directly contributes to a circular economy, waste reduction, and overall resource conservation. It’s a technology that helps industries do more with less, safeguarding our planet for future generations.

Request sample report – Dive into market size, trends, and future

Conclusion

The “Membrane Revolution” it’s a tangible force reshaping the very fabric of industrial operations. By delivering unparalleled precision, efficiency, and sustainability, advanced filtration technologies are empowering industries worldwide to overcome complex challenges and unlock new possibilities. As we navigate the complexities of a resource-constrained world, the role of membranes will only grow, cementing their position as indispensable tools for a cleaner, more efficient, and sustainable industrial future.