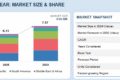

The global variable frequency drive market is projected to reach USD 26.8 billion by 2027 from an estimated USD 21.2 billion in 2022, at a CAGR of 4.8% during the forecast period. Variable frequency drives enable motors to run based on required current demand, rather than running at full speed and reducing output using mechanical controls such as throttles, dampers, or gears. Electric motors can be equipped with frequency converters to operate pumps and fans more efficiently, these factors are expected to drive the demand for global Variable frequency drive market.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=878

The Asia Pacific region is estimated to be the largest market for variable frequency drives, followed by the North America. The Asia Pacific region is also projected to be the fastest-growing market during the forecast period. The increasing investments in LNG, chemical, and mining projects is likely to increase the demand for motors are the key drivers behind the growing demand for industrial buners in the Asia Pacific region.

The variable frequency drive market is served by a mix of large international players with operational presence across the globe and local players commanding a strong supply network in the domestic market. The leading players in the global variable frequency drive market include ABB (Switzerland), Siemens (Germany), Schneider Electric (France), Danfoss (Denmark), and Rockwell Automation (US).

This research report categorizes the variable frequency drive market by type, voltage type, power rating, application, end-user, and region

On the basis of by type:

- AC Drive

- DC Drive

- Servo Drive

On the basis of voltage type:

- Low Voltage

- Medium Voltage

On the basis of power rating:

- Micro Power Drive

- Low Power Drive

- Medium Power Drive

- High Power Drive

On the basis of application:

- Pumps

- Conveyors

- Fans

- Compressors

- Others

On the basis of by end user:

- Oil & gas

- Industrial

- Power

- Infrastructure

On the basis of region:

- Asia Pacific

- Europe

- North America

- Middle East

- Africa

- South America

Recent Developments:

- In April 2021, Siemens introduces a new, compact, and powerful SINAMICS G115D drive system specifically designed for horizontal conveyor applications. The drive system comprises the motor, drive, and gearbox in one unit and is offered in two versions — wall-mounted and motor-mounted.

- In Febraury 2020, Schneider Electric introduced an Altivar 360, a variable speed drive for applications from 0.37 to 22 kW / 0.5 to 30 HP. The compact size of this drive, its robust design, ease of installation, based on the principle of Plug & Play, integrated functions, and macro configuration make it particularly suitable for applications involving industrial machines and certain consumer machines.

- In November 2020, Danfoss Drives and other Danfoss business segments are expected to supply the technology company Wartsila’s research, product development, and production center Smart Technology Hub with a significant number of AC drives and other products.

- In September 2020, ABB invested approximately USD 43.3 million in new research & development facilities and office space for its Motion and Industrial Automation Businesses at the company’s largest Swiss location in Turgi in the canton of Aargau. The investment is expected to enable ABB strengthen its position in a number of high-growth areas while also enabling the company to expand its capabilities in innovation.

Request Sample Pages: https://www.marketsandmarkets.com/requestsampleNew.asp?id=878

Variable frequency drives can reduce energy consumption by up to 60% when integrated into centrifugal fans and pumps. They can also reduce the risk of cavitation in pumps. According to Control Engineering Europe (CEE), efficiency regulations for electric motors came into force in January 2017, requiring all AC motors with a rated output of 0.75–375 kW to run efficiently. With advancements in power electronics technology, the cost and size of variable frequency drives have decreased, while performance has improved. Over the years, energy-efficient electric motors using superior magnetic materials and displaying higher tolerance levels have been developed. High-performance IE4 and IE5 motors offer immediate benefits to OEMs, as well as end users. Limited conventional power generation, coupled with a continuous rise in electricity prices, has encouraged companies to invest in energy-efficient equipment to increase energy efficiency. Energy-intensive industries such as oil & gas, metals & mining, pulp & paper, cement, and water & wastewater treatment are using variable frequency drives to reduce energy consumption and CO2 emissions. Thus, providing ample opportunities for variable frequency drive manufacturers.