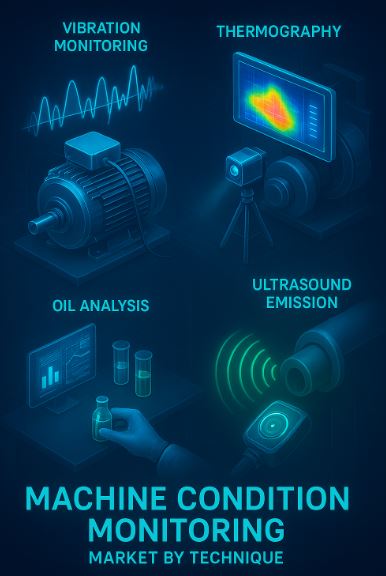

The machine condition monitoring market is an essential segment of the industrial landscape as it helps businesses across sectors to reduce downtime improve productivity and extend the lifespan of machinery by proactively identifying equipment issues before they escalate into costly failures. Driven by advancements in predictive maintenance technologies integration of artificial intelligence and Internet of Things solutions and the rising demand for automation the condition monitoring industry is evolving into a data driven ecosystem. Key techniques such as vibration monitoring thermography oil analysis and ultrasound emission have become the backbone of industrial maintenance practices offering unique insights into the health of rotating equipment motors turbines compressors gearboxes pumps and other critical machinery.

The market has grown significantly in recent years due to the need for operational efficiency energy optimization and safety across industries such as power generation manufacturing oil and gas automotive aerospace food and beverages chemicals and pharmaceuticals. As the global industrial sector adopts digital transformation strategies machine condition monitoring is no longer a reactive or optional measure but a vital approach to predictive and prescriptive maintenance. Vibration monitoring enables early fault detection in rotating machines thermography provides real time visualization of heat patterns oil analysis helps in detecting contamination and wear particles while ultrasound emission identifies leaks and mechanical defects with precision. Together these techniques form a comprehensive framework that supports predictive maintenance strategies enhances plant safety and lowers unplanned downtime costs. The integration of cloud based monitoring platforms wireless sensors and data analytics tools further strengthens the machine condition monitoring market by providing real time insights for decision makers. With industries facing growing pressure to minimize production losses optimize asset utilization and meet sustainability goals condition monitoring techniques are playing a transformative role in shaping the future of industrial reliability and performance.

Vibration Monitoring in Machine Condition Monitoring

- Vibration monitoring is one of the most widely used techniques in the machine condition monitoring market due to its ability to detect faults in rotating equipment such as motors pumps gearboxes bearings and turbines at an early stage.

- It involves measuring vibration signals using accelerometers velocity sensors and displacement probes to identify imbalances misalignments looseness and bearing defects.

- This technique provides real time data on mechanical health enabling predictive maintenance and reducing unexpected failures that can halt production.

- Industries such as oil and gas power generation and automotive heavily rely on vibration monitoring to ensure continuous operation and avoid costly downtime.

- The integration of wireless sensors and cloud based analytics tools has enhanced the effectiveness of vibration monitoring by offering remote access and continuous monitoring capabilities.

- Vibration analysis can identify resonance issues shaft misalignments and lubrication deficiencies thereby extending the life of machinery.

- As industrial automation and smart factories grow vibration monitoring is increasingly combined with artificial intelligence and machine learning algorithms to improve fault diagnosis accuracy.

- The technique is cost effective in the long term because it reduces unplanned downtime maintenance costs and energy consumption while ensuring plant safety.

- Vibration monitoring also supports compliance with industrial safety standards by preventing catastrophic equipment failures.

- With the increasing adoption of condition based maintenance strategies vibration monitoring is expected to continue dominating the machine condition monitoring market in the coming years.

Thermography in Machine Condition Monitoring

- Thermography is a non contact technique that uses infrared cameras to detect temperature variations and heat patterns on the surface of machinery and components.

- It helps in identifying electrical faults mechanical wear thermal overloads insulation failures and hot spots in equipment.

- Thermography is particularly valuable in monitoring motors switchgear bearings conveyors and process equipment where heat anomalies often indicate potential problems.

- This technique allows maintenance teams to visualize invisible issues and address them before they lead to breakdowns.

- Industries such as power generation steel manufacturing cement production and chemical processing frequently use thermography to ensure operational safety.

- Infrared thermography is effective for inspecting high voltage electrical systems transformers circuit breakers and distribution panels without interrupting production.

- The non invasive nature of thermography minimizes risks to operators and enables inspections in hazardous or high temperature environments.

- Integration with predictive analytics platforms enables thermographic data to be combined with other monitoring techniques for comprehensive insights.

- It reduces energy losses caused by faulty electrical connections and improves efficiency by identifying heat leaks in industrial systems.

- As industries increasingly focus on energy efficiency and workplace safety thermography is gaining traction as a core technique in machine condition monitoring.

Oil Analysis in Machine Condition Monitoring

- Oil analysis plays a crucial role in detecting wear particles contamination and chemical properties of lubricants used in industrial machinery.

- By analyzing lubricant samples maintenance teams can detect issues such as metal wear water contamination fuel dilution and oil degradation.

- Oil analysis is widely used for engines gearboxes turbines compressors and hydraulic systems where lubrication health directly impacts equipment performance.

- The technique helps in identifying root causes of machine failures such as poor lubrication improper oil type or contamination before they lead to costly damage.

- Industries such as aviation shipping mining and heavy manufacturing rely on oil analysis for extending equipment life cycles and ensuring operational reliability.

- Advanced oil analysis techniques include spectroscopy ferrography particle counting and viscosity measurement to provide comprehensive insights.

- This proactive approach reduces unplanned maintenance activities lowers downtime and optimizes lubricant usage resulting in cost savings.

- Integration with Internet of Things based sensors enables real time oil condition monitoring without manual sampling thereby enhancing efficiency.

- Oil analysis contributes to sustainability by reducing lubricant wastage and minimizing environmental impact from oil disposal.

- With the rise of predictive maintenance oil analysis is increasingly integrated with other monitoring techniques to provide a holistic view of machine health.

Ultrasound Emission in Machine Condition Monitoring

- Ultrasound emission is an advanced technique that detects high frequency sound waves emitted by machinery components to identify mechanical issues and leaks.

- It is highly effective for detecting compressed air leaks steam leaks vacuum leaks and electrical discharge in high voltage equipment.

- Ultrasound is also used to identify lubrication deficiencies in bearings which can lead to premature failures if not addressed.

- The technique enables early detection of problems that are not visible to the human eye or detectable by vibration monitoring alone.

- Industries such as food processing pharmaceuticals automotive and aerospace adopt ultrasound monitoring to ensure equipment reliability and safety.

- Portable ultrasound devices and handheld detectors make it convenient for maintenance teams to perform inspections quickly and accurately.

- Integration with wireless monitoring systems and data analytics platforms allows continuous ultrasound monitoring in critical applications.

- Ultrasound technology reduces energy costs by identifying leaks in compressed air systems which are among the largest sources of energy loss in manufacturing plants.

- It improves workplace safety by identifying arcing tracking and corona discharges in electrical equipment before they cause accidents.

- As industries demand higher levels of precision and safety ultrasound emission is becoming a preferred monitoring technique in condition monitoring programs.