Predictive maintenance has become a vital strategy in industrial asset management, enabling businesses to anticipate equipment failures before they occur and minimize unplanned downtime. At the heart of this approach lies machine condition monitoring—an evolving field powered by a suite of advanced technologies. These technologies not only ensure the health and longevity of machines but also support data-driven decision-making and cost-effective maintenance strategies. As industries continue to adopt digital transformation practices, several key predictive maintenance technologies are emerging as game-changers in machine condition monitoring.

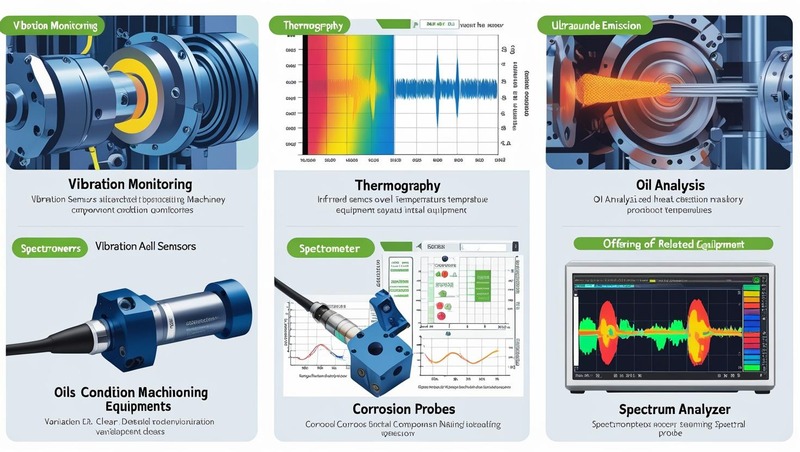

One of the foundational technologies in this space is vibration analysis, which monitors changes in the vibration patterns of machinery to detect imbalances, misalignments, and bearing faults. This technique has become a cornerstone of predictive maintenance, especially in rotating equipment such as motors, pumps, and turbines. By identifying deviations from normal vibration signatures, maintenance teams can take timely action to address developing issues.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=29627363

Ultrasound testing is another highly effective technology that enables the early detection of mechanical and electrical anomalies. It captures high-frequency sound waves emitted by equipment under stress or failure, such as air leaks, valve malfunctions, and electrical discharge. The portability and ease of use of ultrasonic devices make them an attractive choice for on-site inspections and routine monitoring.

Infrared thermography offers a non-invasive method to monitor the thermal signature of equipment and electrical systems. Through thermal imaging, this technology detects heat buildup and uneven temperature distribution, often indicative of excessive friction, electrical resistance, or insulation failure. Infrared cameras allow operators to visualize potential problems before they escalate into serious faults, improving both safety and equipment reliability.

Oil analysis, also known as lubricant analysis, plays a crucial role in condition monitoring by examining the quality and properties of lubricants used in machinery. This technique can reveal signs of wear, contamination, and degradation of mechanical components. By monitoring oil condition, operators can extend lubrication intervals, schedule maintenance precisely, and avoid catastrophic failures caused by poor lubrication.

Acoustic emission monitoring is gaining traction as a predictive maintenance tool that detects high-frequency stress waves generated by cracks, friction, or impacts within materials. It is particularly useful for monitoring pressure vessels, bearings, and structural integrity in critical assets. Its ability to identify microscopic changes long before they manifest into visible damage makes it invaluable for early fault detection.

In recent years, IoT-enabled sensors and AI-driven analytics have revolutionized machine condition monitoring. These technologies facilitate real-time data collection from multiple monitoring methods and apply machine learning algorithms to detect patterns, predict failures, and recommend maintenance actions. The integration of AI allows for automated diagnostics and continuous learning from operational data, significantly reducing human error and improving maintenance precision.

As predictive maintenance technologies continue to advance, their integration into smart manufacturing and digital maintenance ecosystems is becoming seamless. These technologies not only help industries reduce downtime and maintenance costs but also contribute to safer, more efficient, and more sustainable operations. In the future, the combination of traditional techniques and intelligent analytics will redefine how industries maintain their critical assets.

Frequently Asked Questions (FAQs) on Machine Condition Monitoring Market

1. What is the total CAGR expected to be recorded for the machine condition monitoring market size during 2024-2029?

The global machine condition monitoring market is expected to record a CAGR of 8.3% from 2024–2029.

2. What are the driving factors for the machine condition monitoring market share?

Rising inclination towards wireless communication technology and growing adoption of predictive maintenance technique to reduce sudden breakdowns are some of the driving factors for the machine condition monitoring market.

3. Which industry will grow at a fast rate in the future?

Automotive and aerospace industry is expected to grow at the highest CAGR during the forecast period.

4. Which are the significant players operating in the machine condition monitoring market?

Emerson Electric Co. (US), Honeywell International Inc. (US), SKF (Sweden), General Electric (US), and Amphenol Corporation (US) are among a few top players in the machine condition monitoring market.