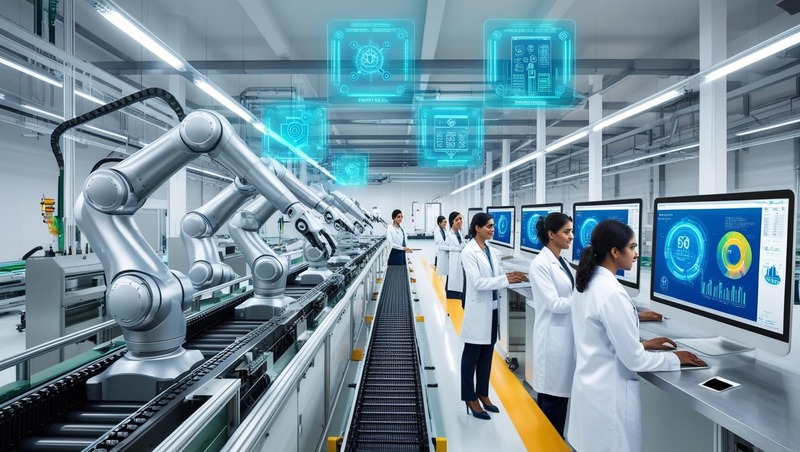

The artificial intelligence (AI) in manufacturing market is poised for rapid expansion between 2023 and 2028, driven by a growing demand for automation, improved operational efficiency, and the widespread adoption of Industry 4.0 technologies. As manufacturers face increasing pressure to reduce costs, enhance productivity, and respond more flexibly to changing market demands, AI has emerged as a transformative force reshaping the industrial landscape.

According to industry analysts, the global AI in manufacturing market is expected to witness a robust compound annual growth rate (CAGR) during the forecast period. Factors such as the integration of machine learning, computer vision, natural language processing, and advanced robotics are contributing to the rapid deployment of AI-driven solutions across factories worldwide. Companies are investing heavily in digital infrastructure and AI platforms to stay competitive and meet rising customer expectations for product quality, customization, and speed.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=72679105

One of the key growth drivers is the increasing adoption of AI-powered predictive maintenance. Manufacturers are using AI algorithms to analyze equipment performance in real-time, predict potential failures, and optimize maintenance schedules. This shift from reactive to predictive maintenance is helping companies reduce unplanned downtime, extend machinery lifespan, and lower maintenance costs.

Another major area of growth is in quality control and defect detection. AI-enabled computer vision systems are replacing manual inspection methods, providing faster and more accurate identification of defects in production lines. These systems help manufacturers ensure consistent product quality, minimize waste, and avoid costly recalls.

Supply chain optimization is also set to benefit significantly from AI advancements. As global supply chains become more complex and vulnerable to disruptions, AI is being used to forecast demand, optimize inventory levels, and enhance logistics efficiency. Between 2023 and 2028, the integration of AI into supply chain management is expected to become a standard practice among leading manufacturers.

Smart factory initiatives will further accelerate AI adoption during the forecast period. AI plays a central role in enabling real-time decision-making, coordinating automated systems, and supporting human-machine collaboration. In these intelligent environments, AI helps manufacturers achieve higher levels of flexibility, responsiveness, and resource efficiency.

Geographically, North America and Asia Pacific are anticipated to lead the AI in manufacturing market growth. The presence of major technology providers, strong R&D investments, and government initiatives to support digital transformation are boosting regional markets. Meanwhile, Europe is also seeing steady growth, particularly in sectors like automotive, aerospace, and pharmaceuticals.

Despite its rapid growth, the market still faces challenges such as high implementation costs, data privacy concerns, and a shortage of skilled AI professionals. However, ongoing advancements in edge computing, cloud AI, and low-code platforms are expected to lower barriers and drive broader adoption in the coming years.

In summary, the 2023–2028 forecast for artificial intelligence in the manufacturing industry paints a promising picture. As AI continues to evolve and prove its value across various manufacturing domains, it will remain a key enabler of digital transformation, innovation, and sustainable growth for the global industrial sector.