Industrial software is undergoing a profound transformation as the global manufacturing and heavy industry sectors embrace digital innovation. Once confined to basic process automation and equipment monitoring,industrial software has become a foundational element in modern operations. The integration of advanced technologies like Artificial Intelligence (AI), Cloud Computing, and the Industrial Internet of Things (IIoT) is accelerating the pace of this evolution. These innovations are not only making factories smarter and more autonomous but are also fueling impressive market growth, with the global industrial software market projected to experience double-digit growth over the next decade.

The increasing convergence of digital technologies with industrial operations is enabling companies to reduce operational costs, improve productivity, increase safety, and become more resilient to global disruptions .Explore how AI, cloud, and IIoT are shaping the future of industrial software and why these trends are redefining the competitive landscape across multiple sectors.

The Expanding Scope of Industrial Software

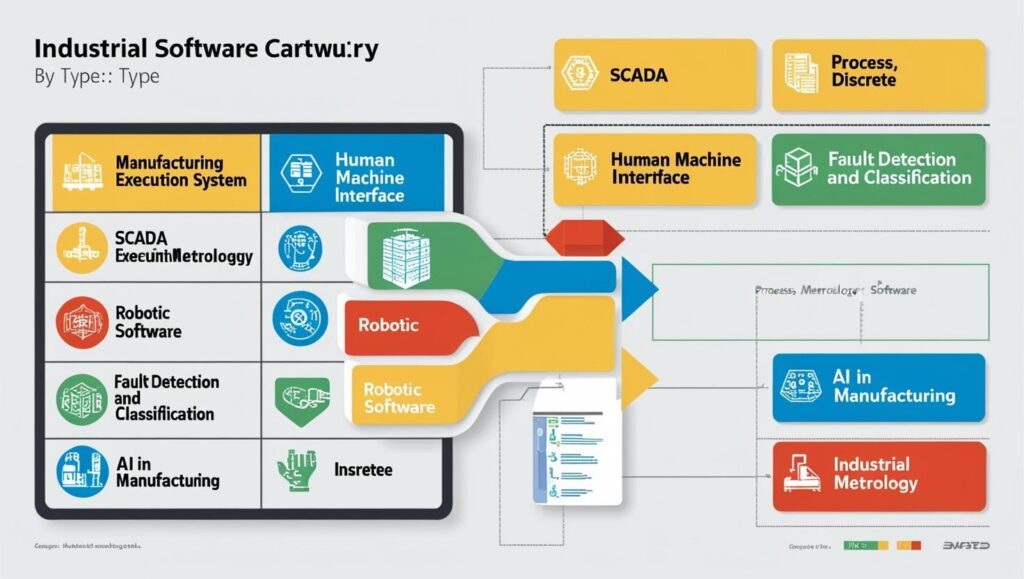

The industrial software market covers a broad range of digital tools used to manage, optimize, and monitor industrial processes. These include enterprise-level systems for asset and lifecycle management, real-time monitoring solutions for production floors, and software for predictive analytics, cybersecurity, and workflow automation. Key domains such as manufacturing execution, energy management, product design, and equipment maintenance are all increasingly software-driven.

As global industries move toward more agile and data-centric operations, the role of industrial software has shifted from supportive to strategic. Software platforms are now central to digital transformation initiatives, enabling companies to unlock new efficiencies, enhance decision-making, and meet the evolving demands of customers and regulators.

AI Takes Center Stage in Industrial Intelligence

Artificial Intelligence is at the core of next-generation industrial software systems. With AI, software is no longer simply reactive—it becomes predictive, autonomous, and adaptive. One of the most significant applications of AI in the industrial space is predictive maintenance. By analyzing machine data, temperature readings, vibration levels, and historical performance, AI can forecast potential equipment failures before they occur. This helps companies prevent costly downtime and avoid unscheduled maintenance, ultimately saving time and money.

AI is also revolutionizing quality assurance. In traditional manufacturing environments, quality control often relies on manual inspections, which are time-consuming and prone to error. AI-driven vision systems and machine learning models can identify defects in products with far greater speed and accuracy, ensuring higher quality standards and consistency.

Moreover, AI enables real-time process optimization. Software can now analyze production variables, learn from outcomes, and automatically adjust parameters to improve efficiency. This allows factories to operate in a more agile and responsive manner, adapting quickly to changes in demand or supply chain disruptions.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=27555137

Cloud Computing Transforms Software Delivery and Scalability

Cloud computing is playing a pivotal role in the digital transformation of industrial operations. Unlike traditional on-premises solutions, cloud-based software platforms offer unparalleled scalability, accessibility, and flexibility. Manufacturers can now deploy applications across multiple sites without the need for expensive infrastructure investments, significantly lowering the barrier to entry for small and mid-sized firms.

Cloud solutions also facilitate remote monitoring and collaboration. Factory managers, technicians, and engineers can access real-time operational data from any location, enabling quicker decision-making and reducing the need for on-site presence. This has become particularly important in the post-pandemic era, where remote work and distributed teams are more common.

Another advantage of cloud computing is the ability to continuously update software platforms without disrupting operations. Providers can deliver regular enhancements, security patches, and AI model improvements in real-time, ensuring that users always have access to the latest features and protections. In addition, cloud environments support big data analytics and machine learning training at scale, something that is often impractical with on-premise solutions.

The Industrial Internet of Things: Connecting Machines to Intelligence

The Industrial Internet of Things has become the digital nervous system of the modern factory. IIoT refers to the vast network of interconnected devices, sensors, and machines that collect and transmit data across the enterprise. These data streams provide the raw material for intelligent decision-making and automation in industrial software.

With IIoT integration, companies can achieve real-time visibility into their assets, processes, and supply chains. Sensors embedded in equipment monitor temperature, vibration, usage, and environmental conditions, feeding data into analytics platforms for immediate processing. This enables condition-based monitoring, which allows maintenance to be performed precisely when needed, instead of on a fixed schedule.

Digital twins are another transformative innovation enabled by IIoT. A digital twin is a virtual replica of a physical asset or system that reflects its real-time state based on sensor data. Engineers and operators can use digital twins to simulate changes, test outcomes, and monitor performance without interrupting actual operations. This significantly reduces the risks and costs associated with system updates, design modifications, and new product introductions.

IIoT also plays a key role in integrating the supply chain. By connecting machines, warehouses, and logistics systems, industrial software can ensure better coordination between production schedules and inventory management, minimizing waste and improving time-to-market.

Cybersecurity Becomes a Strategic Priority

As industrial systems become more connected and software-centric, cybersecurity concerns are mounting. Industrial networks, once isolated from the internet, are now part of the broader digital ecosystem. This exposes them to a growing range of cyber threats, including ransomware, data breaches, and attacks on critical infrastructure.

To address these challenges, industrial software platforms are adopting advanced security protocols, including zero-trust architectures, encryption, access controls, and real-time threat detection. AI-powered cybersecurity solutions are increasingly being used to identify anomalies, recognize suspicious patterns, and respond to threats before they cause harm.

Given the potentially catastrophic consequences of cyberattacks on industrial operations, cybersecurity is no longer viewed as a technical requirement—it is a board-level concern and a critical aspect of risk management. Vendors and manufacturers alike are investing in building secure-by-design systems that prioritize resilience and operational continuity.

Sector-Specific Use Cases and Impact

The adoption of AI, cloud, and IIoT technologies is driving measurable impact across multiple industrial sectors. In the automotive industry, for example, manufacturers are using AI to optimize production lines, detect component defects, and simulate vehicle performance using digital twins. In aerospace, industrial software is enabling more efficient lifecycle management of complex parts and systems, reducing maintenance costs and improving safety.

Energy and utilities companies are using IIoT-enabled software to manage distributed assets such as wind turbines, solar farms, and smart grids. These systems monitor performance, predict maintenance needs, and optimize energy output based on real-time environmental data. Construction firms are leveraging cloud-based platforms and mobile software to coordinate projects, track resources, and improve site safety.

Across all these sectors, industrial software is helping organizations meet new regulatory requirements, enhance productivity, and compete more effectively in a global market.

The Rise of New Business Models and Ecosystems

The rapid evolution of industrial software is also giving rise to new business models and ecosystems. Instead of one-time license purchases, many companies are now adopting subscription-based models, where they pay for software as a service (SaaS). This shift not only reduces upfront costs but also provides vendors with recurring revenue streams and deeper customer engagement.

Software marketplaces and integration platforms are becoming increasingly popular, allowing users to mix and match tools from different providers. This modular approach offers greater flexibility and ensures that companies can tailor their technology stack to specific needs. As a result, partnerships between legacy industrial players and emerging tech startups are growing, creating dynamic ecosystems that foster innovation.

Looking Ahead: What the Future Holds

The future of industrial software lies in further integration and intelligence. Edge computing will become more prominent, enabling data processing closer to machines and reducing latency. Human-machine interfaces will evolve through advancements in natural language processing and augmented reality, making software more accessible to frontline workers.

Low-code and no-code platforms will empower operators and engineers to build their own applications without needing advanced programming skills. Meanwhile, sustainability will become a central theme, with software increasingly used to monitor emissions, reduce energy use, and support environmental compliance.

As industries become more interconnected and data-driven, industrial software will serve as the command center for orchestrating complex, global operations. Those who invest early in these technologies will be best positioned to lead in efficiency, innovation, and market responsiveness.

Industrial software is no longer just a tool—it is a strategic enabler of growth, resilience, and transformation. The combined power of AI, cloud, and IIoT is unlocking new levels of operational intelligence and flexibility across industries. As the demand for digital capabilities continues to rise, the industrial software market is poised for sustained double-digit growth.

To remain competitive, organizations must not only adopt these technologies but also rethink their operational models, workforce strategies, and cybersecurity frameworks. The digital future of industry is already here, and industrial software is the engine driving it forward.

About MarketsandMarkets™

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ’GIVE Growth’ principle, we work with several Forbes Global 2000 B2B companies – helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact:

Mr. Aashish Mehra

MarketsandMarkets™ INC.

630 Dundee Road

Suite 430

Northbrook, IL 60062

USA : 1-888-600-6441