The manufacturing world is undergoing a rapid digital transformation, driven by the need for greater efficiency, precision, and real-time insights. Among the core technologies enabling this transformation, the 3D metrology industry stands out as a pivotal force. Once seen as a specialized tool for quality control, 3D metrology has evolved into an integral component of smart manufacturing, enabling accurate data capture, improved process automation, and seamless integration between physical and digital systems.

The Growing Role of 3D Metrology in Smart Manufacturing

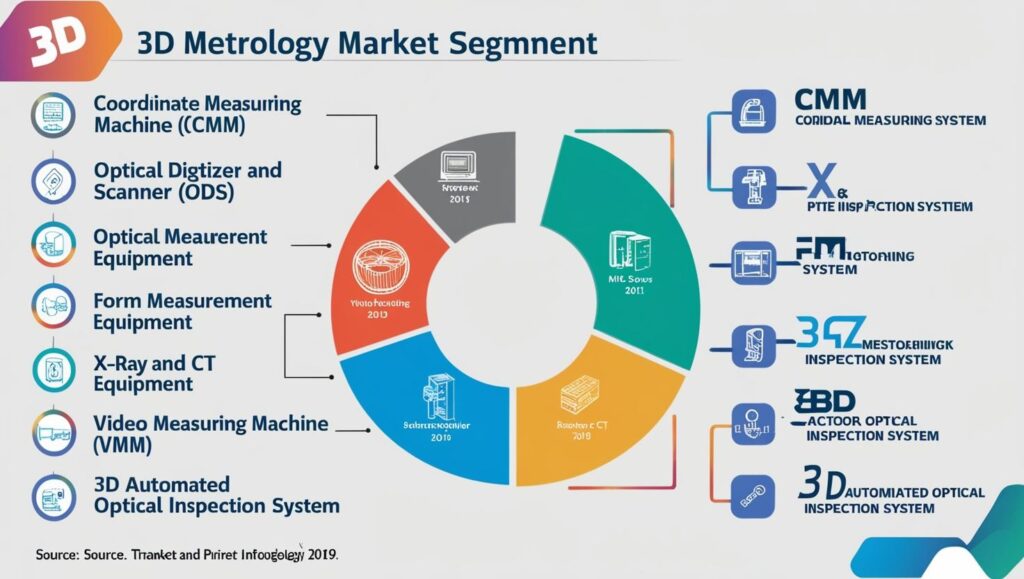

3D metrology refers to the science of measuring physical objects in three dimensions using advanced technologies such as coordinate measuring machines (CMMs), laser scanners, structured light systems, and CT imaging. These tools capture detailed geometric data, enabling precise inspection, reverse engineering, and quality assurance. In today’s digital factories, this capability is no longer optional—it is foundational. Manufacturers increasingly rely on 3D metrology to reduce waste, ensure part integrity, and deliver products with tight tolerances and consistent quality.

In smart factories, 3D measurement data is used not only at the end of production for inspection but is also embedded into the production process itself. This integration allows for real-time monitoring and instant feedback loops, ensuring that defects are caught early and processes are adjusted automatically. As a result, manufacturers benefit from improved yield, shorter cycle times, and significantly lower costs due to rework or recalls.

Accelerating Digital Twins and Simulation-Based Design

One of the most important synergies between 3D metrology and digital transformation lies in its role in creating accurate digital twins. A digital twin is a virtual replica of a physical object, process, or system. 3D metrology provides the highly accurate geometric data needed to build these twins, which can then be used in simulation, analysis, and optimization tasks.

With precise measurement data, engineers can test how a product will behave under different conditions without building multiple physical prototypes. This not only accelerates design cycles but also enables predictive maintenance, real-time monitoring, and long-term performance analysis. In aerospace, automotive, and heavy industries, digital twins built using 3D metrology data are helping reduce downtime and optimize system performance over time.

The global 3D metrology market was estimated to be valued at USD 11.13 billion in 2024 and is projected to reach USD 15.01 billion by 2029; it is expected to register a CAGR of 6.2% during the forecast period.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=203080758

Industry-Specific Innovations and Demands

The 3D metrology industry is finding unique and growing demand across sectors. In the automotive industry, for instance, it is used to inspect large components like body panels and chassis assemblies with millimeter precision. These insights are essential in maintaining high safety standards and design consistency across global production lines. Similarly, in aerospace and defense, where component failures can have catastrophic consequences, metrology ensures every part meets the highest possible standards.

In the electronics sector, the shrinking size of components and the increasing complexity of printed circuit boards demand inspection systems capable of ultra-fine, non-contact measurement. Medical device manufacturers also rely heavily on 3D metrology to verify the accuracy of surgical tools, implants, and prosthetics, where human lives depend on precision.

Integration with Automation, AI, and Connectivity

As manufacturers strive for full automation, the 3D metrology industry is increasingly converging with robotics and artificial intelligence. Automated inspection systems now feature robotic arms equipped with 3D scanners that can inspect parts directly on the production line. These systems operate continuously and require minimal human supervision, enabling higher throughput and faster decision-making.

Artificial intelligence enhances the value of 3D measurement by analyzing complex data sets, identifying patterns, and predicting potential defects. Machine learning algorithms can be trained to recognize subtle variations in product geometry that may indicate future performance issues, enabling preventative actions rather than reactive corrections.

Additionally, connectivity via Industrial Internet of Things (IIoT) platforms allows 3D measurement data to be shared across departments, sites, and even between partners in a supply chain. This connected approach ensures a unified view of quality and performance, fostering transparency, traceability, and collaboration.

Sustainability and Cost Efficiency

Sustainability is becoming a central focus for manufacturing, and 3D metrology contributes significantly by reducing material waste and energy consumption. By identifying deviations and inefficiencies early in the production process, manufacturers can avoid scrap and optimize the use of raw materials. Furthermore, digital simulations and virtual prototyping reduce the need for physical trial-and-error testing, cutting down on resources used during development.

In addition to environmental benefits, the cost savings achieved through improved precision and automation are considerable. Companies adopting advanced 3D metrology solutions report lower rework rates, fewer warranty claims, and better utilization of skilled labor.

The Future Outlook for 3D Metrology

The future of the 3D metrology industry is deeply intertwined with advancements in computing, optics, and machine learning. Emerging trends include miniaturized metrology tools for use in tight or mobile environments, cloud-based metrology platforms for remote access and analysis, and increasingly intuitive software interfaces that make complex measurement tasks accessible to a wider range of users.

As digital transformation becomes the standard rather than the exception, the demand for real-time, high-precision measurement solutions will continue to grow. The next generation of manufacturing will rely not only on what is made, but how precisely and intelligently it is made—and 3D metrology will be at the core of that evolution.

The 3D metrology industry is no longer a support function—it is a strategic enabler of digital transformation in manufacturing. By providing accurate, actionable insights and integrating seamlessly with digital ecosystems, 3D metrology technologies empower manufacturers to innovate, optimize, and compete in a highly demanding global market. As the manufacturing landscape becomes more connected, automated, and intelligent, the role of 3D metrology will only grow in significance.

About MarketsandMarkets™

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ’GIVE Growth’ principle, we work with several Forbes Global 2000 B2B companies – helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103

Delray Beach, FL 33445

USA : 1-888-600-6441