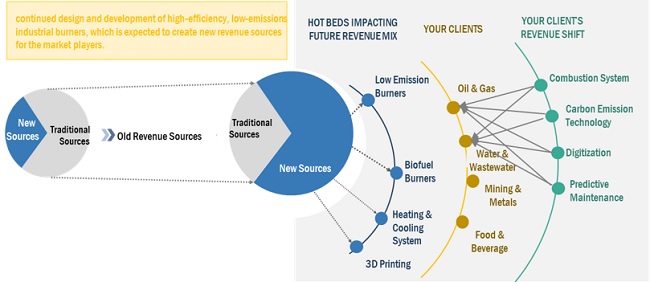

New Revenue Pockets:

The global industrial burner market is expected to grow at a CAGR of 6.1% to USD 7.9 billion by 2027, up from an estimated USD 5.9 billion in 2022. The increasing power generation worldwide fueling demand for industrial burners to drive the demand for global Industrial burner

Various types of industrial burners are available in the market that can be customized according to the requirement of the end user. The different types of industrial burners include regenerative burners, radiant burners, self-recuperative burners, high thermal release (HTR) burners, and direct-fired burners among others. These burners come with features such as metric designs, reduced NOx emissions and carbon dioxide emissions. Premix, fuel or air staging, internal and exterior flue-gas recirculation, and other technologies that achieve ultra-low NOx emissions with minimum (flue-gas recirculation) FGR may be used in future burner designs.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=86869676

The industrial burner market, by burner type, has been broadly classified into regenerative burner, high thermal release burner, radiant burner, direct-fired burner, self-recuperative burner, and others. Other burner types include ribbon burners, line burners, duct burners, pipe burners, and high-velocity burners. The radiant burner segment is expected to have the largest market share during the forecast period. These burners are used in a wide range of applications ranging from lower temperature applications such as paper drying, medium temperature applications such as ethylene cracking furnaces, and higher temperature minerals processing. The increasing demand from the metals & mining and chemicals industries is expected to fuel the demand for radiant burners during the forecast period.

The industrial burner market, by fuel type, has been segmented into oil, gas, dual fuel and solid fuel. The gas segment, by end user, is expected to be the fastest-growing market during the forecast period. The advantages of gas burners, along with the development of the gas distribution network, are expected to prompt end users to install gas burners for various applications, which would drive the growth of the gas-fired burner market. The increasing technological advancements in hydrogen burners and government initiatives toward the production of H2 provide new opportunities to burner manufacturers.

Request Sample Pages: https://www.marketsandmarkets.com/requestsampleNew.asp?id=86869676

Aging power generation infrastructure and increasing refurbishment of industrial burners used in other applications and development of sophisticated liquid and gas burners with 3D printing technology provides several new opportunities for industrial burner providers. Developed countries such as the US, Canada, the UK, and Germany have aging power infrastructure and associated with low efficiency levels and high carbon emissions. These old power plants and industrial infrastructure are scheduled to be phased out soon. Hence, power plant extensions and replacements with new and refurbished industrial boilers and other auxiliary components, including industrial burners, is required for the upgrade of aging power generation infrastructure. Thus, providing ample opportunities for industrial burner manufacturers.