The industrial landscape is undergoing a technological revolution, and one of the most impactful changes is occurring in non-destructive testing (NDT) and inspection systems. Traditionally, NDT inspections—critical for ensuring the quality and safety of components in industries such as aerospace, automotive, energy, and manufacturing—relied heavily on manual processes. These methods, while effective, were often time-consuming, labor-intensive, and prone to human error.

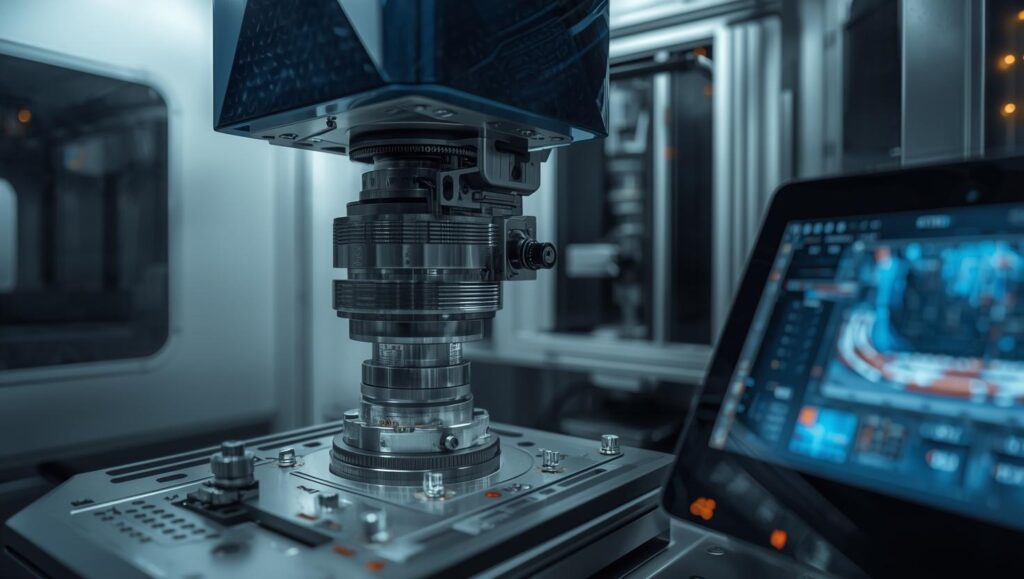

Enter automation. Automated stationary NDT and inspection systems are now redefining how industries monitor, analyze, and validate the integrity of materials and products. By combining robotics, advanced sensors, imaging technologies, and software-driven analytics, automated systems offer unprecedented precision, efficiency, and repeatability, fundamentally transforming the market.

Driving Forces Behind Automation in NDT

Several factors are accelerating the adoption of automation in stationary NDT and inspection systems. Rising quality standards, tighter regulatory compliance, and the demand for faster production cycles are all compelling manufacturers to invest in automated solutions.

Industries such as aerospace and automotive are particularly reliant on high-precision inspection, where even minor defects can have catastrophic consequences. Automated NDT systems provide consistent, reproducible results, eliminating variability caused by human inspectors and significantly reducing the risk of defective components reaching the market.

Additionally, digital transformation and Industry 4.0 initiatives are playing a major role. Connected systems, IoT-enabled sensors, and data analytics allow for real-time monitoring and predictive insights, enabling companies to make faster, data-driven decisions.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=233564506

Technological Innovations in Automated Stationary NDT

Automated stationary NDT systems encompass a variety of technologies. Ultrasonic testing (UT), X-ray and computed tomography (CT), eddy current testing (ECT), and magnetic particle inspection (MPI) are increasingly being integrated into robotic inspection platforms.

These systems often feature multi-axis robotic arms that can navigate complex geometries, coupled with high-resolution sensors that detect flaws invisible to the human eye. Software algorithms then analyze the data in real time, flagging defects, generating reports, and even predicting potential failures.

Emerging technologies like AI-powered image recognition and machine learning analytics are further enhancing the accuracy and efficiency of automated inspections. For example, machine learning models can be trained on historical inspection data to identify subtle patterns that indicate material fatigue or micro-cracks, which might otherwise go unnoticed.

Benefits of Automation in Stationary NDT

The advantages of automation in stationary NDT systems are substantial. First and foremost is enhanced precision. Automated systems maintain a consistent testing methodology, reducing human error and increasing reliability.

Secondly, automation leads to higher throughput and efficiency. Tasks that previously took hours can now be completed in a fraction of the time, helping manufacturers meet production deadlines without compromising quality.

Safety is another critical factor. Automated inspection systems reduce human exposure to hazardous materials, radiation, or confined spaces, creating safer working conditions across industries.

Finally, automation improves data management and traceability. Digital records of every inspection are automatically stored, making it easier to track compliance, perform audits, and generate insights for continuous improvement.

Market Growth and Investment Opportunities

Automated Stationary NDT & Inspection Systems Industry worth $1,195.9 million by 2030, The global market for automated stationary NDT and inspection systems is growing rapidly, fueled by industrial demand, regulatory pressure, and technological innovation. Key players are investing in R&D for smarter, faster, and more adaptable inspection systems, while startups are introducing AI-driven solutions to disrupt traditional NDT methods.

Industries are recognizing the ROI of automation, not just in reduced labor costs but also in improved product quality, decreased downtime, and fewer recalls. Investors see significant opportunities in companies developing advanced sensors, AI-based analytics, and robotic integration for NDT applications.

Challenges and Considerations

Despite the benefits, the transition to automated NDT systems comes with challenges. High upfront costs for equipment, integration complexity with existing production lines, and the need for specialized technical expertise can slow adoption. Additionally, standardization across industries and regions remains a concern, requiring harmonized protocols to ensure consistent inspection outcomes.

However, as technology matures and economies of scale improve, these challenges are gradually being mitigated. The long-term advantages—accuracy, efficiency, safety, and data-driven insights—make automation a strategic investment for manufacturers worldwide.

Conclusion: The Future of NDT is Automated

Automation is no longer an optional enhancement in NDT and inspection—it is rapidly becoming the industry standard. By leveraging robotics, advanced sensors, and AI-driven analytics, automated stationary NDT systems are transforming how industries ensure quality, safety, and compliance.

As global demand for high-precision, high-volume manufacturing grows, the market for automated NDT and inspection systems is set for sustained expansion. Companies that embrace automation today will benefit from improved operational efficiency, reduced risk, and a competitive edge in a rapidly evolving industrial landscape.

FAQ: Automated Stationary NDT & Inspection Systems Market

Q1. What are automated stationary NDT & inspection systems?

Automated stationary NDT (Non-Destructive Testing) systems are industrial inspection solutions that use robotics, sensors, and software to evaluate materials or components without causing damage. They are widely used in aerospace, automotive, energy, and manufacturing sectors to detect defects, ensure quality, and maintain safety standards.

Q2. Why is automation gaining traction in the NDT market?

Automation is driven by the need for higher precision, faster inspection cycles, and enhanced safety. Manual inspections can be inconsistent, time-consuming, and prone to human error. Automated systems provide consistent results, real-time data analytics, and reduced exposure to hazardous conditions, making them an attractive investment for manufacturers.

Q3. What technologies are used in automated NDT systems?

Automated systems incorporate technologies such as ultrasonic testing (UT), X-ray and computed tomography (CT), eddy current testing (ECT), and magnetic particle inspection (MPI). Many systems integrate AI and machine learning algorithms to enhance defect detection, pattern recognition, and predictive maintenance.

Q4. Which industries are adopting automated stationary NDT systems the fastest?

Industries with high safety and precision requirements are leading adoption. This includes aerospace, automotive, oil & gas, and energy production. High-volume manufacturing sectors are also investing in automation to improve throughput while maintaining strict quality standards.

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America’s Best Management Consulting Firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. With the widest lens on emerging technologies, we are proficient in co-creating supernormal growth for clients across the globe.

Today, 80% of Fortune 2000 companies rely on MarketsandMarkets, and 90 of the top 100 companies in each sector trust us to accelerate their revenue growth. With a global clientele of over 13,000 organizations, we help businesses thrive in a disruptive ecosystem.

The B2B economy is witnessing the emergence of $25 trillion in new revenue streams that are replacing existing ones within this decade. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ‘GIVE Growth’ principle, we collaborate with several Forbes Global 2000 B2B companies to keep them future-ready. Our insights and strategies are powered by industry experts, cutting-edge AI, and our Market Intelligence Cloud, KnowledgeStore™, which integrates research and provides ecosystem-wide visibility into revenue shifts.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter , LinkedIn and Facebook .

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103, Delray Beach, FL 33445

USA: +1-888-600-6441