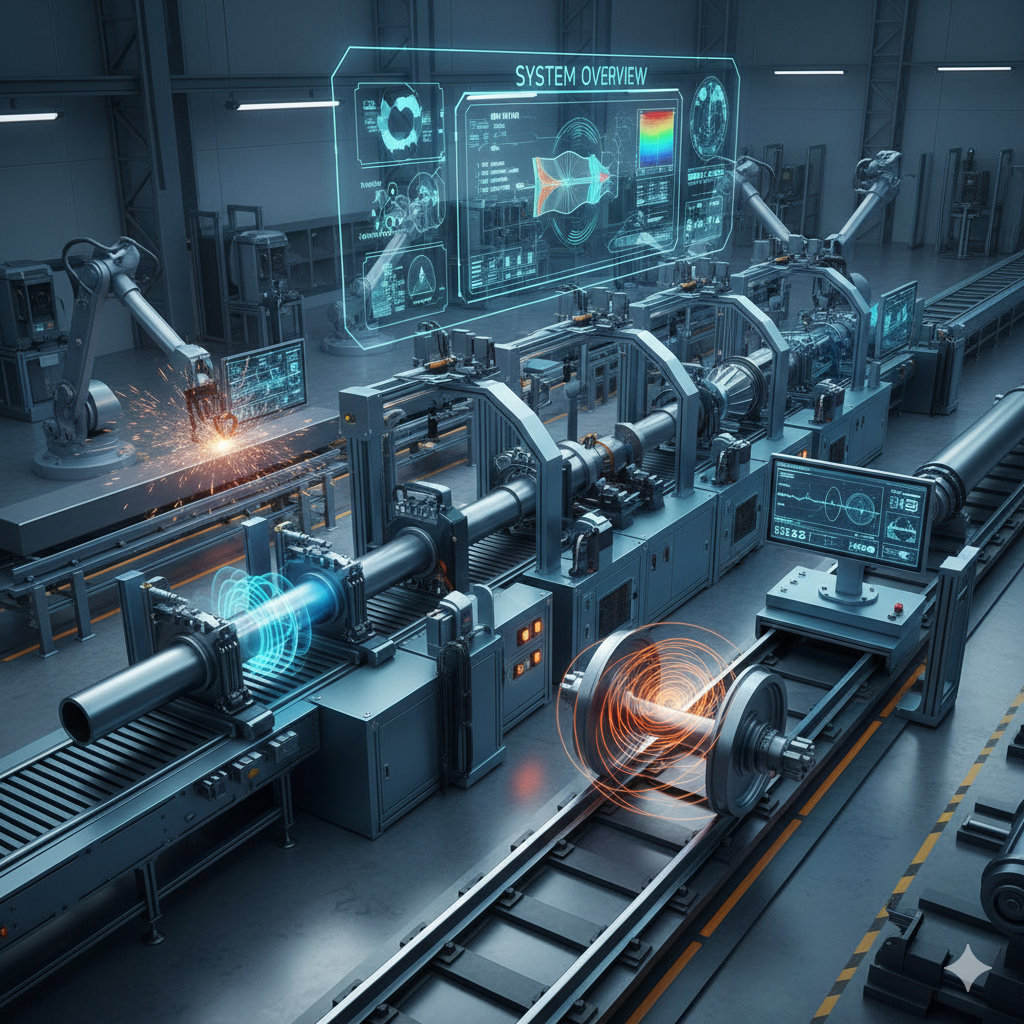

The Automated NDT & Inspection Systems Market is witnessing significant growth as industries prioritize safety, quality, and efficiency in production and maintenance processes. Non-destructive testing (NDT) technologies, such as Ultrasonic Testing (UT), Phased Array Ultrasonic Testing (PAUT), and Eddy Current Testing (ECT), are being integrated into automated, stationary inspection systems, enabling real-time, accurate, and reliable quality control.

The global automated stationary NDT & inspection systems market is expected to grow from USD 767.4 million in 2025 to USD 1,195.9 million by 2030, registering a robust CAGR of 9.3%

Market Segmentation by In-Line System Type

In-line automated inspection systems are transforming industrial operations by providing continuous, real-time monitoring of materials and components. These systems reduce downtime, improve productivity, and ensure compliance with strict safety and quality standards. The adoption of in-line automated NDT systems is a key driver of market growth, particularly in high-volume manufacturing sectors.

Key NDT Technologies Driving Market Growth

Ultrasonic Testing (UT)

UT is a widely used technology in automated inspection systems. It allows precise detection of internal flaws and defects in metals, composites, and welds. The integration of UT into stationary automated systems improves speed, accuracy, and repeatability, making it essential for high-stakes industries like aerospace and oil & gas.

Phased Array Ultrasonic Testing (PAUT)

PAUT enhances traditional UT by using multiple ultrasonic elements to generate highly detailed images of material interiors. Its high resolution and adaptability make it ideal for automated inspection systems, enabling real-time flaw detection and process optimization. The growing demand for PAUT is significantly influencing the Automated NDT & Inspection Systems Market.

Eddy Current Testing (ECT)

ECT is particularly effective for surface and near-surface defect detection in conductive materials. Automated ECT systems are increasingly used in metals, aerospace, and rail industries, where speed, accuracy, and minimal human intervention are critical.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=233564506

Industry Applications Driving Market Opportunities

Metals & Metallurgy: Automated NDT systems detect cracks, inclusions, and other structural defects in metals, enhancing production quality and reducing material waste. The metals sector remains a major contributor to market growth.

Rail Industry: Safety and reliability are paramount in rail operations. Automated NDT systems using UT, PAUT, and ECT help inspect rails, wheels, and critical components for defects, ensuring operational safety and compliance.

Oil & Gas: Pipelines, storage tanks, and refineries require stringent quality control. Automated inspection systems minimize human error while ensuring timely detection of corrosion, cracks, or weld defects, reducing the risk of catastrophic failures.

Aerospace: High-value aerospace components demand precision and reliability. Automated NDT systems enable rapid inspection of airframes, engines, and critical components, supporting safety, compliance, and efficient manufacturing processes.

Future Outlook

The Automated NDT & Inspection Systems Market is expected to grow steadily as industries adopt advanced, automated inspection technologies. Increasing integration of AI, robotics, and real-time data analytics will further enhance system efficiency, defect detection accuracy, and predictive maintenance capabilities.

Manufacturers focusing on multi-technology platforms, such as combining UT, PAUT, and ECT in a single automated system, are poised to capture significant market share. Additionally, industries seeking high throughput, minimal downtime, and stringent quality control will continue to drive market expansion across regions.

Automation in NDT & inspection is revolutionizing quality control across metals, rail, oil & gas, and aerospace industries. By leveraging UT, PAUT, and ECT technologies, automated stationary systems provide unparalleled precision, efficiency, and reliability. The Automated NDT & Inspection Systems Market represents a growing opportunity for manufacturers and end-users committed to safety, operational excellence, and technological advancement.

The future of industrial inspection is automated, accurate, and intelligent, with opportunities spanning multiple high-value sectors.

Automated NDT & Inspection Systems Market FAQ

1. What are Automated NDT & Inspection Systems?

Automated NDT (Non-Destructive Testing) & Inspection Systems are technologies that detect defects and ensure quality in materials and components without causing damage. They integrate automated processes with NDT methods like Ultrasonic Testing (UT), Phased Array Ultrasonic Testing (PAUT), and Eddy Current Testing (ECT) for efficient and reliable inspection.

2. What are the key technologies in the Automated NDT & Inspection Systems Market?

Ultrasonic Testing (UT): Detects internal defects in metals and composites.

Phased Array Ultrasonic Testing (PAUT): Provides detailed imaging for precise flaw detection.

Eddy Current Testing (ECT): Ideal for surface and near-surface defect detection in conductive materials.

3. Which industries are driving the growth of automated NDT systems?

Metals & Metallurgy – Ensures quality and reduces material waste.

Rail – Monitors rails, wheels, and critical components for safety.

Oil & Gas – Inspects pipelines, tanks, and refineries for corrosion and defects.

Aerospace – Ensures precision and safety of airframes, engines, and critical components.

4. What are the advantages of using automated NDT & inspection systems?

Increased inspection speed and accuracy

Reduced human error and downtime

Real-time defect detection and process monitoring

Integration with AI and data analytics for predictive maintenance

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America’s Best Management Consulting Firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. With the widest lens on emerging technologies, we are proficient in co-creating supernormal growth for clients across the globe.

Today, 80% of Fortune 2000 companies rely on MarketsandMarkets, and 90 of the top 100 companies in each sector trust us to accelerate their revenue growth. With a global clientele of over 13,000 organizations, we help businesses thrive in a disruptive ecosystem.

The B2B economy is witnessing the emergence of $25 trillion in new revenue streams that are replacing existing ones within this decade. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ‘GIVE Growth’ principle, we collaborate with several Forbes Global 2000 B2B companies to keep them future-ready. Our insights and strategies are powered by industry experts, cutting-edge AI, and our Market Intelligence Cloud, KnowledgeStore™, which integrates research and provides ecosystem-wide visibility into revenue shifts.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter , LinkedIn and Facebook .

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103, Delray Beach, FL 33445

USA: +1-888-600-6441