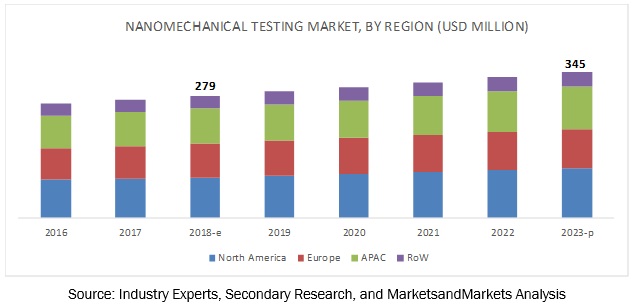

North America is expected to account for the largest size of the overall nanomechanical testing market in 2018. North America is also expected to be the fastest-growing region during the forecast period. The rapid industrialization and high demand for nanomechanical testing instruments for several R&D activities performed by many engineering institutions in this region propel the nanomechanical testing market growth in North America. However, the market in APAC for nanomechanical testing is estimated to grow at an expedited CAGR during the forecast period due to the dynamic changes in the adoption of new technologies and advancements in organizations across industries, as well as increased use of connected devices. This region has become a global focal point for major investments and business expansion opportunities. The market in Asia Pacific is expected to show significant growth in all sectors.

The global nanomechanical testing market is expected to grow from USD 279 million in 2018 to USD 345 million by 2023, at a CAGR of 3.65% from 2018 to 2023. The increasing demand for testing various materials to understand its properties on a nanoscale would increase the market for nanomechanical testing services for several applications, such as life sciences, industrial manufacturing, and material development.

Download PDF Brochure @

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=239461945

Thermal stability of an instrument used for testing is vitally important for obtaining meaningful measurements of the viscoelastic properties of time-dependent materials. As nanoindenters measure very small displacements, high accuracy is necessary; in short, data should not be influenced by any thermal or mechanical drift during the test duration. Nanomechanical testing devices can identify material behavior even when there is a slight change in temperature and strain. Nanomechanical testing devices allow for a minimal drift at room temperature that is usually a considerably less magnitude. Negligible thermal drift is the major advantage offered by nanomechanical testing instruments, which is crucial for companies from different industries who need to analyze the material behavior. There are 3 major types of tests, namely, macroindentation test, microindentation test, and nanoindentation test.

NANOMECHANICAL TESTING MARKET, BY INSTRUMENT TYPE, IS GOING TO SHOW FASTEST GROWTH DURING FORECAST PERIOD

Scanning electron microscopes are most widely used in the study of solid materials. They can be used in varieties of applications, such as research- and industry-related fields where the characterization of solid materials is desirable. SEMs are useful in nanomechanical testing since they can reveal from where indentation started, how fast it propagated, and whether the mode was ductile or brittle. SEMs can also be used to measure the cross-sectional thickness of the metallic coating. SEMs are widely used to identify phases based on qualitative chemical analysis and/or crystalline structure. Dual-beam systems are expected to exhibit the fastest growth during the forecast period. This is due to the ability of the dual-beam systems to accurately measure the forces and deflections at the scale of the objects to be tested. These systems can be used without causing a collision or obstruction of various detectors or sources during the sample testing.

DEVELOPMENTS IN BIOIMPLANT DEVICES GENERATE NEW MARKET OPPORTUNITIES FOR NANOMECHANICAL TESTING EQUIPMENT

Life sciences is a continuously evolving field that requires advanced characterization techniques in the field of biology, pharmaceuticals, and pathology. Additionally, in the field of medical implants and devices, material deformation behavior, compatibility, and reliability are of utmost importance. In life sciences applications, nanomechanical testing solutions are widely used in synthetic biomaterials and biomedical devices that are largely implanted in pacemakers. Biomedical applications of nanomechanical testing solutions include measurement of the strain rate sensitivity of interconnect technology in pacemakers.

A range of players such as Bruker, Micro Materials, and Nanoscience Instruments offer multiple test equipment for use in biomedical materials testing. For instance, Nanoscience Instruments offers Nano Indenter G200, which can measure the deformation over 6 orders of magnitude, and even modular options can be added to accommodate a variety of applications making it suitable for biomedical materials. On the other hand, Bruker offers nanomechanical and nanotribological test equipment and techniques for a range of life sciences applications starting with understanding single-cell mechanics and measuring pharmaceutical-induced mechanical property changes to quantifying interfacial adhesion strength of drug-eluting coatings and wear characteristics of implants.