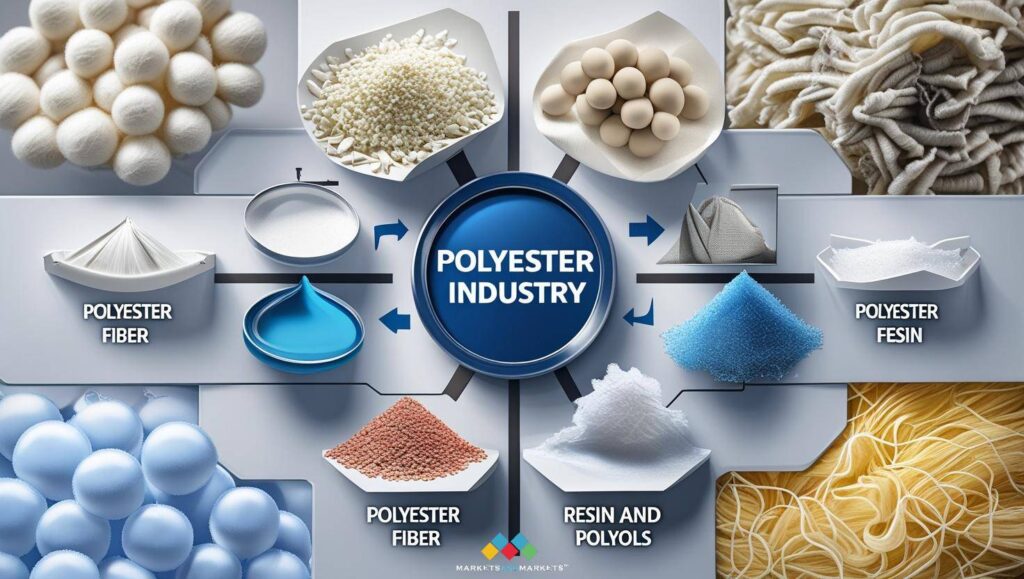

As sustainability and innovation reshape the textile and chemical industries, polyester remains a cornerstone material—thanks to its durability, versatility, and recyclability. From polyester fabric recycling to the rising demand in polyester staple fiber and polyester polyol markets, the polyester landscape is evolving rapidly. This blog explores key trends, market movements, and production insights across various polyester products, providing an overview tailored for industry leaders, manufacturers, and market watchers.

The Rise of Polyester: Fiber, Resin & Polyols

Polyester, a synthetic polymer derived from petroleum-based raw materials, dominates textile and plastic applications globally. A wide range of products, from polyester fiber and polyester resin to polyester polyols, are reshaping industries including apparel, automotive, construction, and packaging.

In particular, polyester fiber from PET bottles is gaining attention as sustainability pressures increase. Recycled PET (rPET) enables a circular economy in the textile value chain, reducing dependence on virgin resources.

Polyester Fiber Market & Manufacturing Process

The polyester fiber market is expanding significantly due to its growing use in home textiles, automotive interiors, apparel, and geotextiles. Polyester fibers are categorized as polyester staple fiber and filament fiber, with staple fibers mimicking the properties of natural cotton.

Polyester fiber market is estimated at USD 102.2 billion in 2023 and is projected to reach USD 151.6 billion by 2028, at a CAGR of 8.2% from 2023 to 2028.

Key production stages involve:

- Polymerization of PET chips

- Melt spinning

- Drawing and cutting

These steps form the backbone of the polyester fiber production process and are crucial for achieving consistent fiber strength and quality.

Countries like Vietnam and Indonesia are emerging as global hubs. A polyester staple fiber manufacturer in Vietnam or a polyester staple fiber manufacturer in Indonesia can offer cost-effective, high-volume production with growing export capacity.

Polyester Fabric Recycling & Circular Initiatives

Polyester fabric recycling has become a vital sustainability strategy. Recycling methods—such as mechanical recycling of clear PET bottles and chemical depolymerization—are helping industries meet environmental compliance and reduce landfill waste.

Polyester recycle trends are being shaped by innovations in sorting technology, closed-loop manufacturing, and growing consumer demand for eco-friendly fabrics.

Polyester Polyols and Their Expanding Market

Polyester polyols—crucial raw materials for polyurethane production—are now widely used in adhesives, flexible foams, and automotive coatings. The polyester polyol market is gaining traction due to increased demand in construction and furniture sectors.

With a dedicated HS code, polyester polyol manufacturers are scaling production across Asia, Europe, and North America. The polyester polyols market is being driven by the adoption of sustainable building practices and automotive light-weighting strategies.

Polyester Resins: From Unsaturated to Versatile Applications

Polyester resin, particularly unsaturated polyester resin, is used in composites, marine components, and electrical insulations. The polyester resins market is forecasted to grow steadily, driven by its thermosetting properties, low shrinkage, and excellent mechanical performance.

Manufacturers are expanding their polyester resin product lines for niche applications like FRP (fiber-reinforced plastics) and specialty coatings.

Polyester Film & Powder Coating Applications

Beyond fibers and resins, polyester film holds significant value in the packaging and electronics industries. The polyester film industry in India, in particular, is booming due to rising demand in flexible packaging and solar panel backsheet production.

Polyester powder coating offers corrosion resistance and weatherability, making it ideal for architectural applications. These coatings are solvent-free and eco-friendly, aligning with current green manufacturing trends.

Market Outlook and Pricing Trends

The polyester market size is projected to experience robust growth, driven by global demand for synthetic fibers, recycled PET, and polyurethane applications. Competitive polyester pricing across Asian markets is also enabling greater accessibility for manufacturers and consumers alike.

Industry experts are closely tracking:

- PET resin fluctuations

- Government regulations on plastic usage

- Shifting demand between staple fiber and filament fiber

Global Supply Chain & Regional Growth Hubs

Asia-Pacific dominates the polyester manufacturing landscape, with China and India as key players. The polyester manufacturing process—available in detail through industry whitepapers and PDF resources—requires advanced technology for polymerization, extrusion, and finishing.

From polyester yarn production process to polyester staple fiber production, scalability and automation are critical for meeting international quality standards and delivery timelines.

Download PDF brochure for deeper insights :

From production to recycling, the polyester value chain is undergoing a dynamic transformation. Whether it’s the expanding polyester fiber market, innovative polyester resin products, or sustainable polyester polyol solutions, the future of polyester is increasingly driven by circularity, technology, and global collaboration. As a global material with local impacts, polyester continues to be a focal point of innovation and growth—across fibers, resins, films, and coatings. Businesses that adapt to market trends, optimize their polyester production process, and invest in recycling infrastructure will be well-positioned to lead the next phase of sustainable material development.