On the basis of end user, the bioprocess containers market is segmented into pharmaceutical & biopharmaceutical companies, CROs & CMOs, and academic & research institutes. In 2020, the pharmaceutical & biopharmaceutical companies segment accounted for the largest share of the bioprocess containers market.

The demand for biopharmaceuticals among the senior population is increasing as the elderly are more prone to various diseases/disorders that can be treated using biologics.

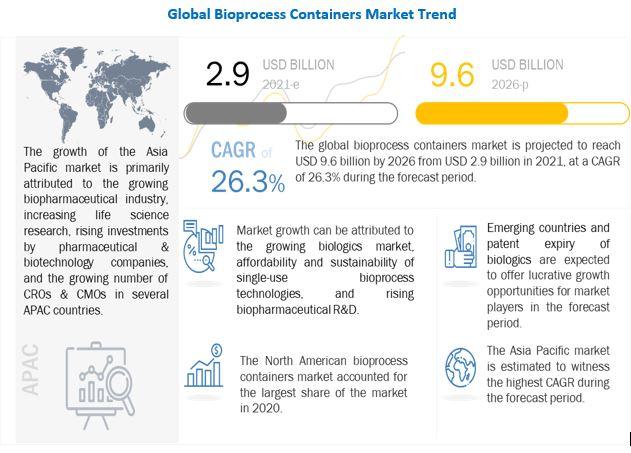

[216 Pages Report] The global bioprocess containers market is projected to grow from USD 2.9 billion in 2021 to USD 9.6 billion by 2026, at a CAGR of 26.3% during the forecast period. Growth in the bioprocess containers market is mainly driven by factors such as the growing biologics market, affordability and sustainability of single-use bioprocess technologies, and rising biopharmaceutical R&D.

Since most of the leading COVID-19 vaccine programs are using novel approaches, including mRNA, DNA vaccine, and vectors, these platforms are largely built on single-use technology. Most of the pandemic-related new facilities are largely engaging single-use systems due to their flexibility combined with high speed and much lower capital investment compared to traditional stainless steel equipment.

Therefore, the growing adoption of single-use technologies for COVID-19 pandemic-related research, coupled with increasing vaccine development by key players, is expected to have a positive impact on the bioprocess containers market.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=107645832

The growth of single-use technologies can be attributed to the growing need for better, cheaper, and faster biologics production. Active development of individualized biologics and personalized medicines, including patient-specific cellular & gene therapies and therapeutic vaccines, demands high sterility and is therefore manufactured using single-use equipment and consumables.

Extractables are compounds that can be extracted from source materials using appropriate solvents under vigorous laboratory conditions, while leachables are compounds present in drug products caused by leaching from containers, closures, and processing components. Therefore, leachables can be considered a subset of extractables.

Extractables and leachables are commonly associated with polymeric and elastomeric materials due to the use of additives to increase stability and aid in the formation of material components.