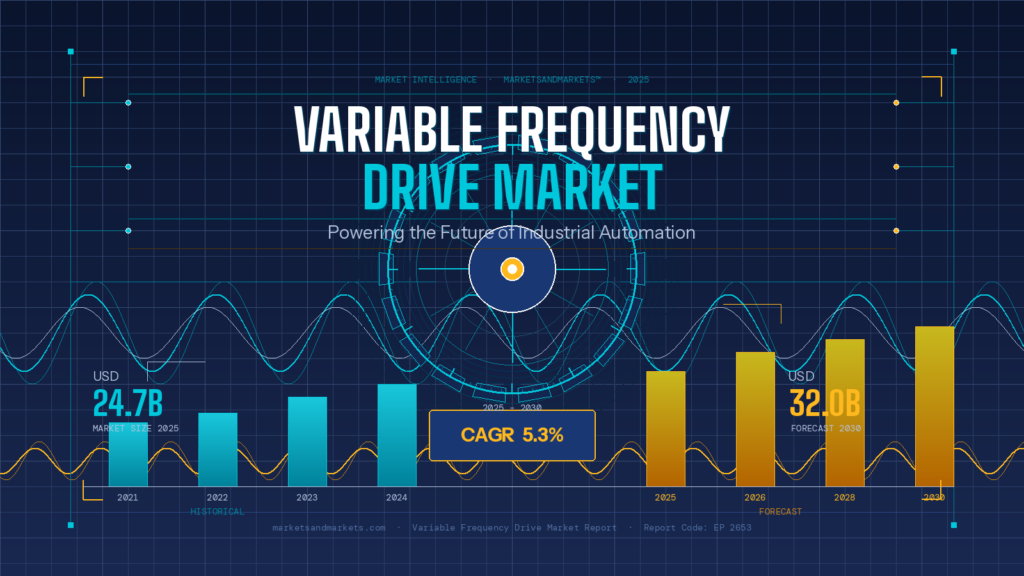

Variable Frequency Drive Market Size and Forecast

The Variable Frequency Drive market is projected to grow from USD 24.7 billion in 2025 to USD 32.0 billion by 2030, registering a Compound Annual Growth Rate (CAGR) of 5.3% during the forecast period. This expansion is underpinned by two converging forces: the increasing industrialization of emerging economies and the urgent need to reduce energy consumption across manufacturing, oil and gas, water treatment, and power generation sectors.

Market Size (2025): USD 24.7 Billion

Market Forecast (2030): USD 32.0 Billion

CAGR (2025–2030): 5.3%

These numbers tell a story of quiet but consistent growth — a market that is not chasing hype but is instead anchored in fundamental industrial necessity. Industries worldwide are under mounting regulatory and competitive pressure to maximize motor performance while reducing operating costs, and VFDs are the most proven technology for achieving both simultaneously.

Download PDF Brochure – http://www.marketsandmarkets.com/pdfdownloadNew.asp?id=878

What Is Driving VFD Market Growth?

1. The Urgent Push for Energy Efficiency

The industrial sector reportedly consumes 37% of the energy used globally, while buildings account for another 30%. Governments from Washington to Beijing are rolling out stricter energy-efficiency mandates, carbon reduction targets, and green industrial policies. VFDs are front and center of every response strategy. When a motor is fitted with a VFD in a centrifugal load application — such as pumps, fans, or compressors — the efficiency gains are dramatic: integrating VFDs with compressors alone can reduce energy consumption by 20 to 50 percent, depending on the application.

2. Industrial Automation and Motion Control Demand

The rise of smart factories and automated production lines has created insatiable demand for precise motion control systems. Modern manufacturing environments require motors that can accelerate, decelerate, and maintain speed with pinpoint accuracy. AC drives — the dominant VFD type — integrate seamlessly with advanced automation platforms and IoT-enabled industrial systems, making them the default choice for engineers designing next-generation facilities.

3. Government Regulations and Sustainability Goals

Policy tailwinds are a significant accelerator. The U.S. Department of Energy, European Union directives, and Asia Pacific national programs are all driving infrastructure modernization that demands energy-efficient drive technologies. North America alone faces an estimated USD 150 billion annual cost from power disruptions, with Canada requiring a projected USD 400-billion investment in its electricity sector over the next 20 years — investments that will place VFDs at the heart of grid modernization efforts.

4. Industrial IoT and Robotics Integration

The convergence of Industrial Internet of Things (IIoT) platforms with VFD technology is creating a new paradigm: drives that not only control motor speed but also predict maintenance needs, optimize energy consumption in real time, and communicate seamlessly with enterprise automation systems. This integration is unlocking new revenue streams for manufacturers and creating compelling ROI arguments for end users.

Make an Inquiry – https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=878

Key Market Segments: Where the Action Is

By Type: AC Drives Dominate, Servo Drives Surge

The VFD market segments by type into AC Drives, DC Drives, and Servo Drives. AC drives command the largest share because of their superior adaptability, cost-effectiveness, and compatibility with the widest range of industrial applications — from HVAC and pumping systems to conveyor lines and compressors. Their ability to adjust motor frequency based on real operational need makes them the backbone of energy-saving strategies across virtually every sector.

By Voltage: Medium Voltage is the Fastest-Growing Segment

Medium-voltage VFDs — typically deployed for motors operating above 690 V — are experiencing the fastest growth in the market. They are essential for large-scale operations in oil and gas, mining, water treatment, power generation, cement, steel, and chemicals. Their ability to provide precise speed control, extend motor lifespan, lower mechanical stress, and reduce maintenance costs makes them an irresistible investment for industries where operational reliability is non-negotiable.

By Application: Pumps Lead, Compressors are the Growth Star

Pumps represent the largest application segment, owing to their critical role across oil and gas, water and wastewater, mining, chemicals, and pulp and paper industries. However, compressors are the fastest-growing application. VFDs allow compressors to match output to demand dynamically, cutting energy use by up to 50% and extending equipment lifespan — an extraordinary value proposition in industries where compressors operate 24/7.

By Power Rating: Low Power Drives Rule, High Power Drives Rise Fast

Low-power drives (under 6 kW) hold the largest share, driven by massive demand from HVAC, agriculture, water treatment, food and beverage, and light manufacturing. High-power drives, however, are the fastest-growing segment, fueled by modernization and energy-efficiency initiatives in the steel and mining industries, where large-scale equipment demands precise control and maximum efficiency.

By End User: Power Sector Leads; Oil and Gas Surges Back

The power generation sector is the largest end-user of VFDs globally. Utilities and power generators rely on VFDs in draft fans, cooling tower pumps, feedwater pumps, and compressors to optimize internal power consumption. Oil and gas is the second-fastest-growing segment, driven by record capital expenditures in 2024 — particularly in North and Latin America — that are accelerating VFD adoption for drilling operations, pipeline fluid transport, and compressor management.

Request sample pages of the report – https://www.marketsandmarkets.com/requestsampleNew.asp?id=878

Trends and Disruptions Reshaping the VFD Industry

AI and Generative AI Integration

Artificial intelligence is moving from the periphery to the core of VFD technology. AI-driven predictive maintenance algorithms are being embedded directly into drive platforms, enabling systems to anticipate failures before they occur, schedule maintenance proactively, and continuously optimize energy consumption without human intervention. Companies like WEG are already leading this charge — their acquisition of BirminD has strengthened capabilities in industrial analytics, sensor diagnostics, and AI-driven process control.

IoT-Enabled Smart Drives

Connected VFDs that communicate with plant-wide IoT platforms are transforming how industrial facilities manage their energy and maintenance profiles. Real-time data from thousands of drive units can be aggregated, analyzed, and acted upon at a system level — a capability that is redefining what operational efficiency means in a smart manufacturing context.

Renewable Energy Integration and Decentralized Power

As industries integrate renewable energy sources into their operations, VFDs play a critical role in managing the variability and intermittency of solar and wind power. Decentralized power generation models, where facilities generate and manage their own electricity, require sophisticated motor control solutions that only modern VFD platforms can provide.

Gray Market Challenge: Quality and Innovation at Risk

Not all growth trends are positive. The VFD market faces a persistent challenge from gray market players offering low-cost alternatives that undercut pricing but fail to deliver advanced features, after-sales support, or adherence to industrial standards. This dynamic suppresses innovation adoption and creates reliability risks in critical industrial applications. Leading manufacturers are responding through customer education, product authentication programs, and cost-competitive solutions that don’t sacrifice quality.